It is without a doubt that eCommerce has shaped a new revolution in logistics. Whether automating supply chain processes or providing same-day delivery to their customers, they have done it all by integrating technology into their operations, improving supply chain visibility and efficiency. On the other hand, the ease of eCommerce is also due to the easy accessibility and availability of the option of product return in case the customer is unsatisfied with their product purchase for various reasons. The convenience of buying your favourite item online and getting delivered to your doorstep knowing you will be able to return it in case you don’t like it has shifted shopping patterns from millions of customers from brick and mortar stores to eCommerce. However, return shipping is not without caveats for businesses as the process that deals with return shipping, called reverse logistics, is complicated and has several associated challenges.

Understanding reverse logistics

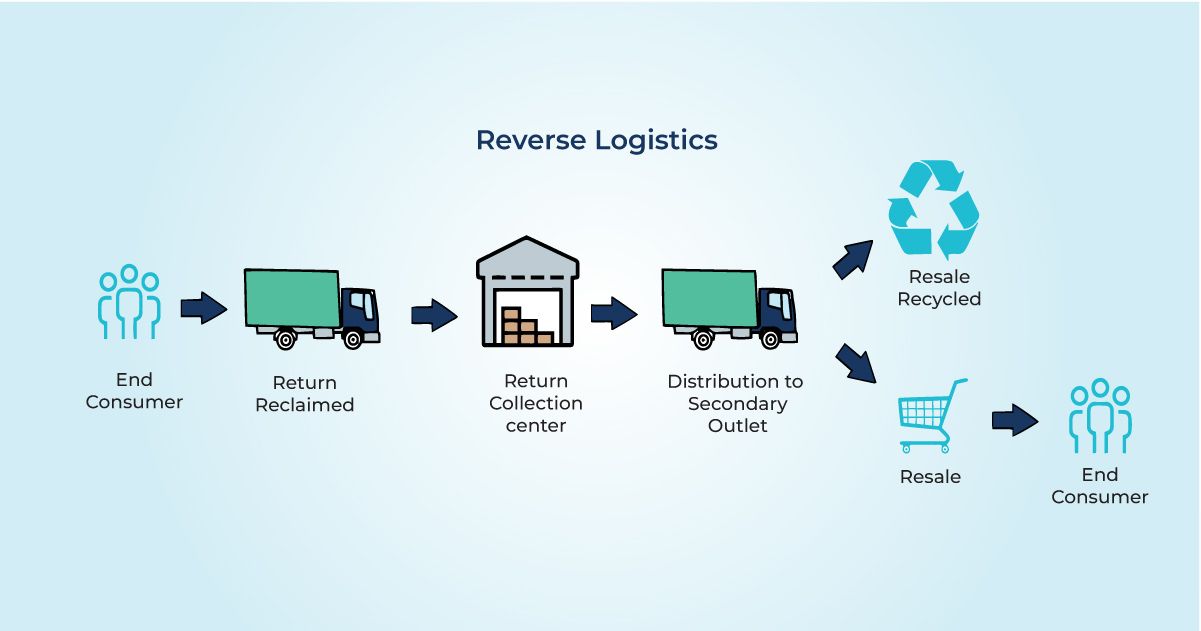

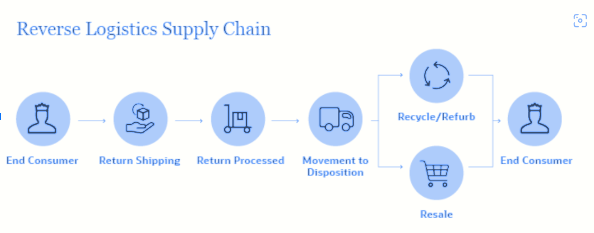

Reverse logistics, known by several other terms like return shipping, return management and so on, deal with the return supply chain of goods from the end-user to the manufacturer. In other words, reverse logistics is traditional logistics, just in reverse. To understand reverse logistics, one needs to get a crisp understanding of how traditional logistics work.

Let’s take the example of someone purchasing a t-shirt through Amazon. Once the customer purchases the t-shirt through their portal, the traditional supply chain process is followed to the last-mile delivery. If the customer is not satisfied, they file for a return. The process of reverse supply chain begins from here.

To understand some statistics on the scale of return logistics in India, Statista Research Department published the data on return logistics data according to which total return on forwarded orders stands at 20% for 2019 and 17% for 2020. The apparel industry's return rates are as high as 40% in certain markets.

In theory, reverse logistics would involve the same set of steps that are followed in traditional logistics. The process starts with the customer filing for a product return, which is generally checked to ensure all the conditions for return are met, including the invoice or tags at a local drop point or by the individual assigned for pick up at home. Post verification, the product is repacked and shipped to the retailer’s manufacturing unit/warehouse through several transportation channels. Once the retailer receives the product, they can decide what they want to do with it. The product is either recycled, refurbished or resold depending on the production condition.

The cost of return shipping is relatively high for the value of the product returned in eCommerce. On average, product returns adds anywhere between 8-10% of the cost price to the total cost price of the product. To better explain, the cost of reverse logistics of a product is usually 1.5x higher than the cost of forward logistics. There are several reasons for the same, which are addressed ahead in the article.

Process of reverse logistics in the industrial sector

Return shipping in the industrial sector is a common occurrence as well. It is primarily related to managing returns and buying surplus goods and materials. However, the process and steps vary across industries.

For example, in the Food & Beverage industry, companies have to deal with returning packaging material & pallets and rejected food shipments too. Both these processes are incredibly challenging, and logistical challenges arise from food spoilage, tampering and other issues resulting from delays in the logistics process. On the other hand, reverse logistics in the beverage industry involves using empty tap containers to recapture the value of containers by reusing them, thus, creating value through reverse logistics.

Whereas, in the construction industry, reverse logistics is associated with transporting materials to and from to new sites. Other processes such as recycling, reuse, waste reduction and utilisation are also essential aspects of reverse logistics in the industry.

The need for reverse logistics in eCommerce

Historically, the need for reverse logistics has always existed. Because there are times when the shipment does not arrive in the condition or shape that the purchaser expected, the purchaser rejects the shipment, and it is returned to the manufacturer or business. Once they receive the shipment, they can decide what to do with it.

However, in the eCommerce sector, the reasons for return shipping vary since the manufacturer directly deals with the consumer. Consider the last few times you purchased a product online through an eCommerce aggregator like Amazon and Flipkart or a company’s website. The reasons for the return or replacement could have been one of the following:

- The packaging was damaged.

- The product was not functioning correctly.

- The packaging seal of the product is broken

- Did not receive the right product

- In the case of clothing items, the product was not of the appropriate size

- The product was not similar to the description and images available at the time of purchase.

Besides several genuine reasons, customers also return their products or file for a replacement for other benign reasons. As a result, the entire process of replacement or return becomes complicated, and naturally, malpractices are also a common practice when it comes to returning shipping.

Despite the challenges and hurdle,s almost every company that offers online purchases have to provide replacement or return options with their own set of criteria and guidelines. Only of the critical reasons for it is earning customers’ trust. Since eCommerce is solely based on customers making purchases online based on images, descriptions and customer reviews, they must have a redressal mechanism in case they receive a purchase which does not live up to their expectations. Considering the competition and availability of alternatives, businesses must be cautious with logistics to retain the customer’s trust and perception of the broader market.

Challenges associated with reverse logistics

The biggest challenge associated with reverse logistics is the fact that the burden of return falls mainly on the retailer. Even in the case of the sale made through eCommerce aggregators like Amazon, sellers are either charged by amazon to handle their returns, or sellers have to manage their returns through other logistics providers such as 3PL providers. As a result, reverse logistics put additional costs on businesses in an industry with already razor-thin margins.

The primary issue is the lack of data that hinders demand forecasting for reverse logistics. The typical metrics like geographical location, product type, quantity and quality of the product that help businesses predict demand in forward logistics are quite uncertain to determine in the case of reverse logistics. When it comes to eCommerce the situation is even more complicated since the platform has to deal with multiple sellers of the same product.

Additionally, a report by Mckinsey highlights that more than 50% of the businesses in the world do not have a specialised team or individual dedicated to reverse logistics. Consequently, that results in a lack of accountability which hampers the scope of improvement in the operations.

Several businesses across the world also lack the appropriate technology and subsequent optimisation that is required to manage reverse logistics. Over-reliance on manual intervention and traditional methods leads to supply chain visibility issues leading to increased cases of malpractices, a high scope of error and reduced efficiency, ultimately costing the business.

Lastly, in the case of eCommerce, a generous replace/return policy to customers without proper assessment of the capacity to process them leads to delays in managing and processing returned goods. It not only slows down the process and leads to poor customer experience but also leads to loss of inventory particularly in the case of goods with shorter shelf life.

Conclusion

Despite the challenges, businesses and eCommerce aggregators cannot turn away from reverse logistics. The demand for reverse logistics will tremendously grow as we see a shift in consumer shopping from brick-and-mortar stores to online shopping/eCommerce. However, businesses can understand the challenges they face by implementing available supply chain technologies and collecting and analysing data on reverse logistics better. Moreover, companies need to collectively work on optimising their replace/return policies which are more in touch with the existing capacities to process. Lastly, reducing the time it takes for a product to return to the seller and become available for resale needs to be reduced to avoid inventory wastage and lead to more optimum utilisation of resources. Reverse logistics in a broader context is also crucial for the success of a circular economy and for making the supply chain more sustainable. A more sustainable supply chain is not just good for the environment. Still, it would also help businesses recapture value at every step of the supply chain process in both forward and reverse logistics.

What is reverse logistics?

Supply chain management that sends goods back from buyers to sellers or producers is known as reverse logistics. Reverse logistics are needed for procedures like returns or recycling after a customer receives a product.

Why reverse logistics is required?

When a finished good needs to return via the supply chain from where it came, reverse logistics is required (usually from the customer back to the manufacturer or supplier).