Preventive maintenance is one of the most affordable ways to increase a vehicle's lifespan, boost fleet efficiency, and reduce vehicle breakdowns, hence maintenance of fleet is important. Preventive maintenance that is scheduled optimizes uptime, guarantees the security of your assets while they are in movement, and provides up to a 545% ROI.

Assets and vehicles can live much longer with preventive maintenance which reduces the replacement chances, and if there are fewer chances of replacement, the ROI will increase automatically. In addition, as maintenance checks are usually carried out after hours, costs associated with downtime are normally not increased. Ignoring routine preventative maintenance tasks can eventually affect a business's financial status.

In our previous blog, we discussed what preventive maintenance is and how the checklist should be carried out. In this blog, we’ll go in-depth about defects and inspections done for preventive maintenance and how checklists are made.

Preventive Maintenance Inspections

Preventive Maintenance Inspection is a methodical procedure for determining performance flaws and indications of degradation in any asset , fleet or piece of equipment through the evaluation of its present state. Since the inspection identifies problems and specifies a maintenance scope, maintenance frequently comes after the inspection. These are simple checks that can assist identify wear or damage early on, preventing the need for major component repairs. These inspections cover particular items, like record repairs, routine repairs, indicate inspection interval, indicate repair/replace, etc. Pre- and post-inspections are two different sorts of inspections that are performed.

Pre/Post Trip inspection

Establishing effective communication between drivers and management is a crucial component of preventive maintenance. Pre-trip inspections done properly prevent the driver from leaving the facility in a vehicle that has an unfixed issue. A thorough post-trip inspection allows the shop enough time to address any issues that are found before the truck is sent back out on the road.

The use of the driver's daily vehicle inspection checklist, which is either a pre-trip or post-trip inspection, is a simple technique to ensure and document vehicle data. Every good and complete inspection demands trained drivers, but the driver should also be able to spot any faults and report them immediately. All checklists must be kept in the vehicle's permanent file so that information is always accessible and may be reviewed as needed. The vehicle driver must clearly complete and sign the pre- and post-trip inspection paperwork.

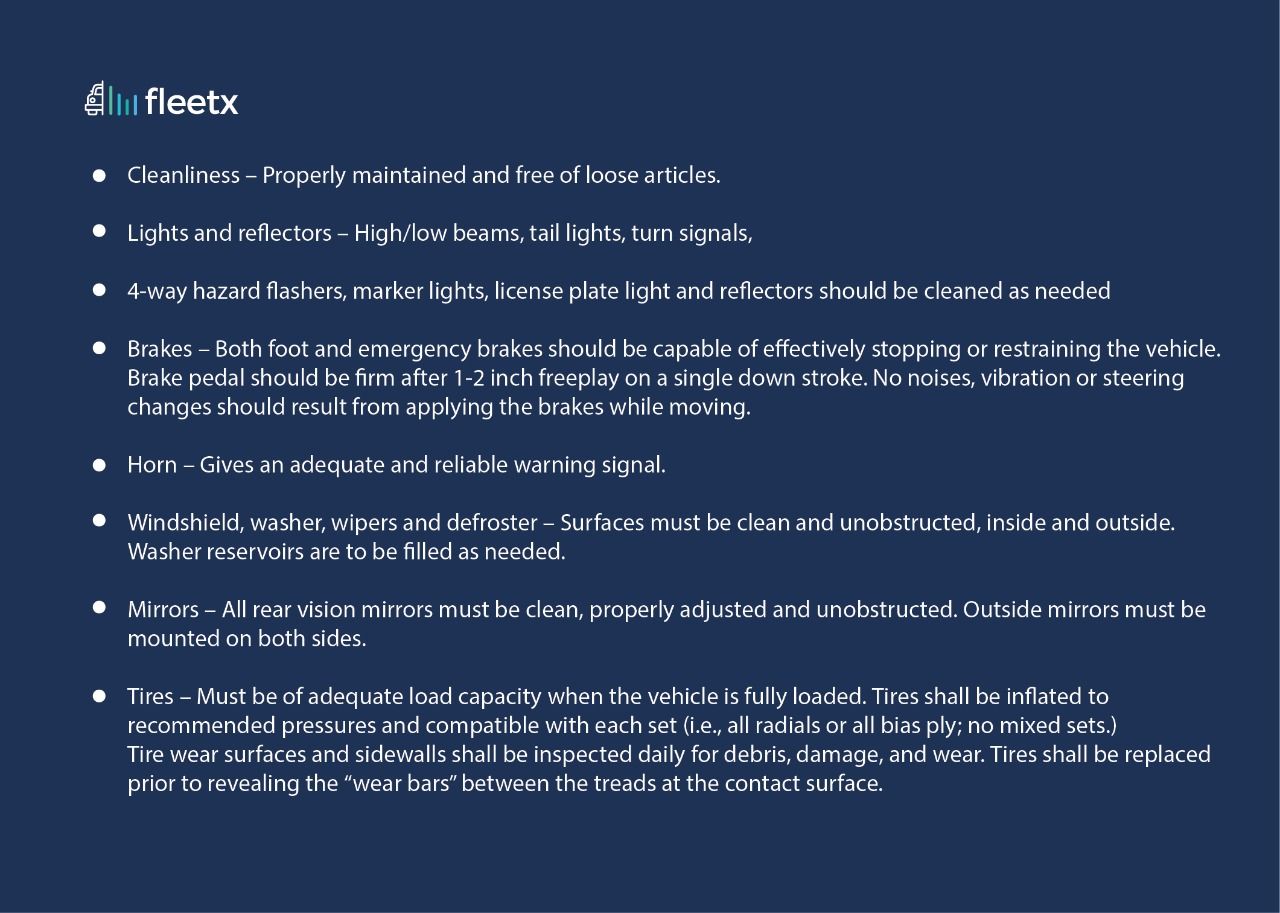

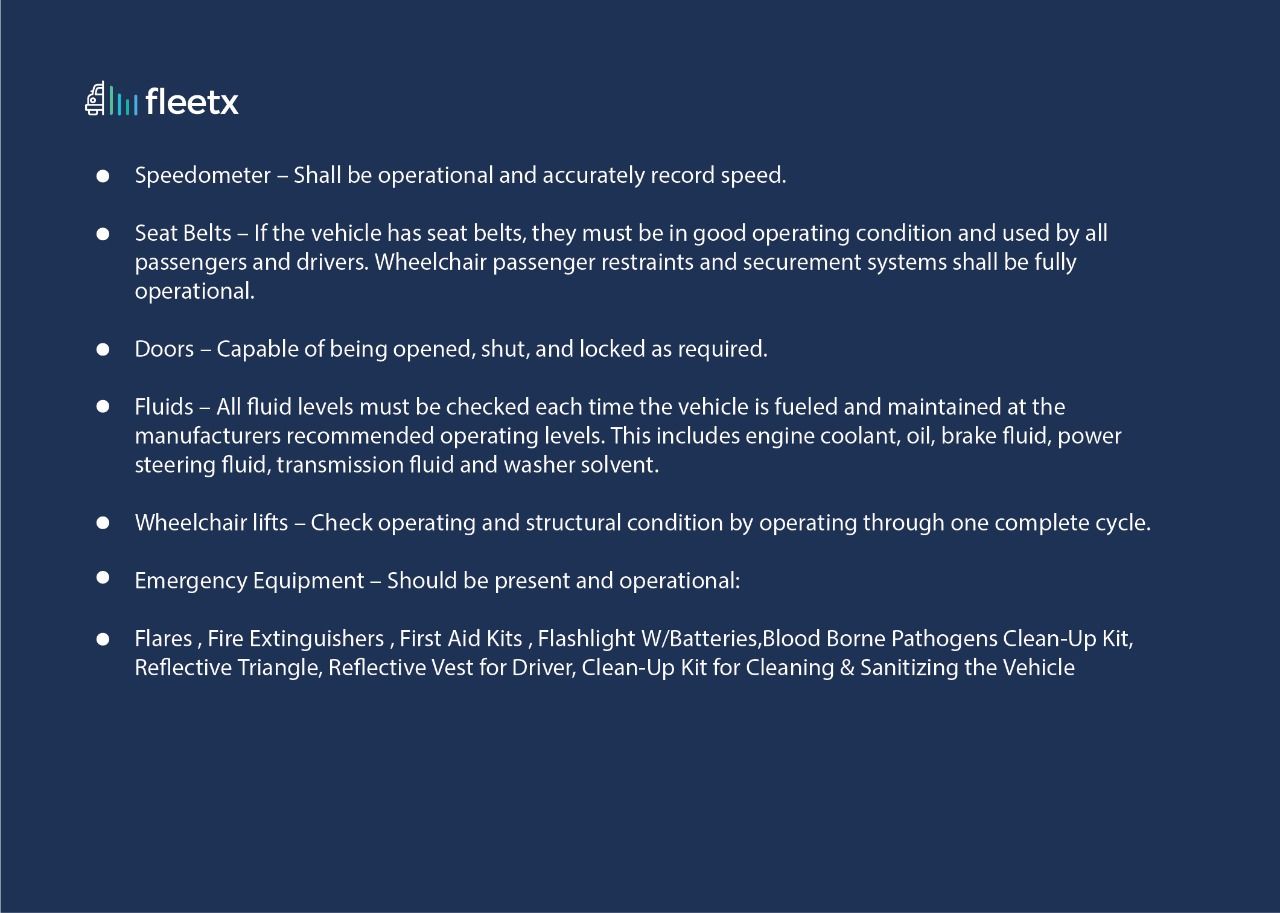

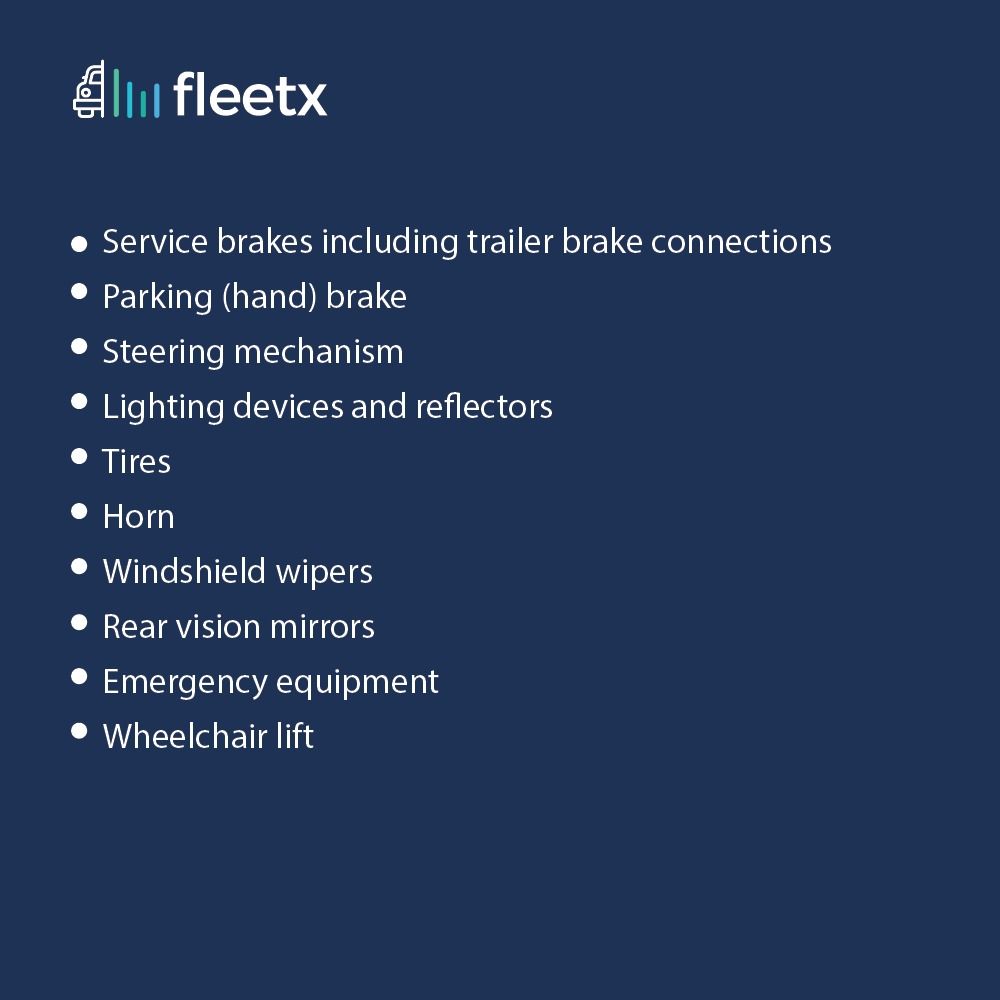

The following items should be checked during a pre-trip and post-trip inspection, at the very least, per reports on vehicle fleet maintenance:

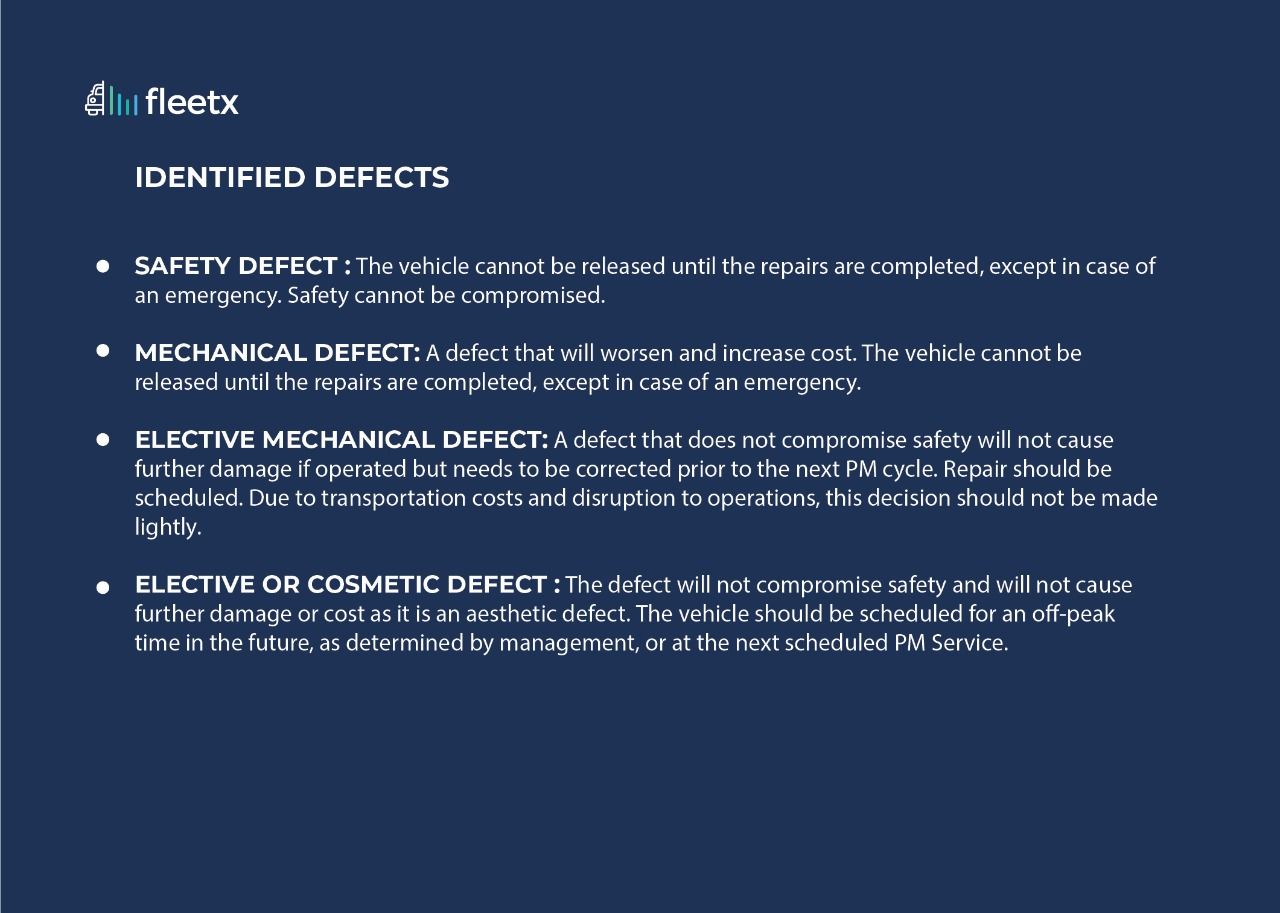

Drivers should report any defects found during the specified set of inspections as soon as feasible because they could impact vehicle operation and safety and cause a breakdown.

Steps to create a plan for preventive maintenance

Each firm has a unique mix of assets and fleets, and each has varied needs and demands based on those needs. There will never be a set maintenance checklist, but the quality will always depend on how well you understand the requirements for your fleets and machinery.

Vehicle data, best maintenance practices, and adjusting it to your company's needs are all steps in the process of developing your own checklists for your organization. Here are some recommendations to get you going with it:

Valuable data: Be specific with all the assets and vehicle models for each item on your checklist. The paperwork and documentation should be created meticulously so that it can be evaluated as needed. Your technicians and drivers will do duties correctly if you are precise and specific in your instructions.

Potential Team: While working on the preventive maintenance plan , there are different types of assets and they all need different levels of supervision. All the different kinds of jobs need different expertise and it is important to have the right people onboard, so that valuable insights can be taken into consideration.

Safety guidelines: Be sure to include any necessary safety precautions when drafting the preventive maintenance task for your list. Include safety cautions for each checklist.

Regular update: Your PM checklist should be revised frequently to reflect equipment upgrades, business expansion, problems your maintenance team encounters, modifications to standard operating procedures, and adjustments to production methods. Remote access to the checklist makes it simpler because it provides access from anywhere at any time. As they may send notifications and reminders, remote updates can enable holding sessions on a regular calendar basis.

To Conclude

Preventive maintenance helps companies to manage compliance and inspection requirements, it extends the life of equipment, saves downtime, eliminates demands for maintenance costs, and avoids expensive emergency repairs. Having an efficient maintenance inspection is crucial, and it should be carried out since it brings the important components of fleets and assets together. Thus, sticking to a solid preventive maintenance plan makes it simple for technicians, drivers, and benefits the overall revenue of the business.