Fleet preventive maintenance is the greatest strategy to lessen and prevent vehicle breakdowns. Preventive maintenance (PM) initiatives that are carefully organized generate significant savings. According to research, preventive maintenance can reduce maintenance costs of fleets by up to 18 percent. Preventive maintenance is calculated based on the amount of fuel used, mileage, time, or engine running hours. Preventive maintenance plans set off procedures including vehicle inspection, cleaning, testing, repairs, part replacement, lubrication, and other continuing vehicle maintenance procedures when certain thresholds are reached.

Fleets benefit from preventive maintenance since it's better to carry out scheduled maintenance than to remove a vehicle from operation for unplanned breakdowns and repairs. Routine maintenance appointments lower the possibility of unanticipated equipment failures that incur emergency repair costs. High priority work orders are required for emergency maintenance, which is costly. By increasing the service life of your vehicles, preventive maintenance can lower long-term costs. In addition, it contributes to the road safety and safety of your vehicle drivers.

Every successful PM programme starts out with a plan. We'll go through the essential checklist and procedures for performing preventive maintenance in this article.

Why is it vital to have a fleet preventative maintenance programme?

When properly executed, preventive maintenance programmes offer businesses a reliable foundation of standard operating procedures. By identifying and resolving issues before they become serious, preventive maintenance contributes to extending a vehicle's lifespan. As the problems are resolved before they become major issues, it helps in making improvements over time and also assists in lowering the liability by decreasing the risk of recurring failures. Preventive maintenance also helps to reduce repair expenses and can help in planning in advance.

What are the types of Fleet Preventive maintenance?

Usage-based preventive maintenance: This maintenance is done when the vehicle is really used. This kind of maintenance forecasts a future inspection or maintenance task's due date by taking into consideration a vehicle's typical daily usage or exposure to environmental conditions.

Calendar/time-based preventive maintenance: This maintenance is carried out at a predetermined time, according to a calendar interval. When the due date approaches and the required work orders have been prepared, the maintenance action is initiated.

Predictive maintenance: This maintenance is intended to plan corrective maintenance procedures ahead of a failure. To estimate when maintenance should be carried out, the team must first assess the vehicle's condition. After that, maintenance tasks are planned to avoid unplanned vehicle breakdowns.

Prescriptive maintenance: Prescriptive maintenance not only predicts when and where failure will occur, but also explains why it is occurring. In order to reduce any danger to the operation, this kind of maintenance assists in the analysis and determination of many choices and probable results.

How should a Preventive Maintenance plan be carried out?

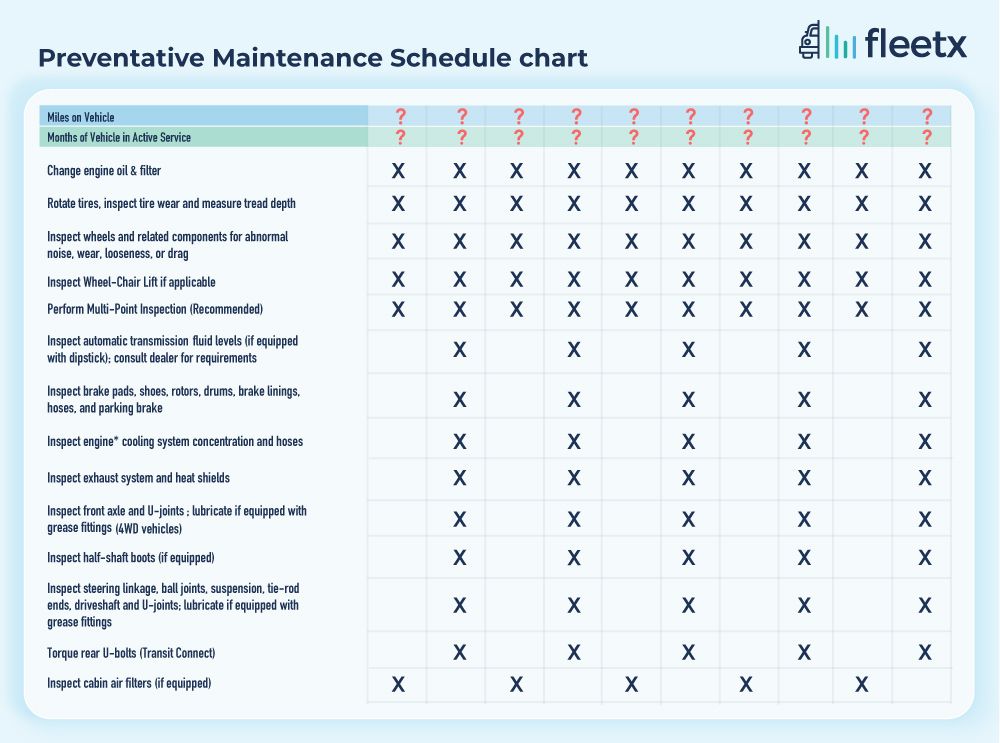

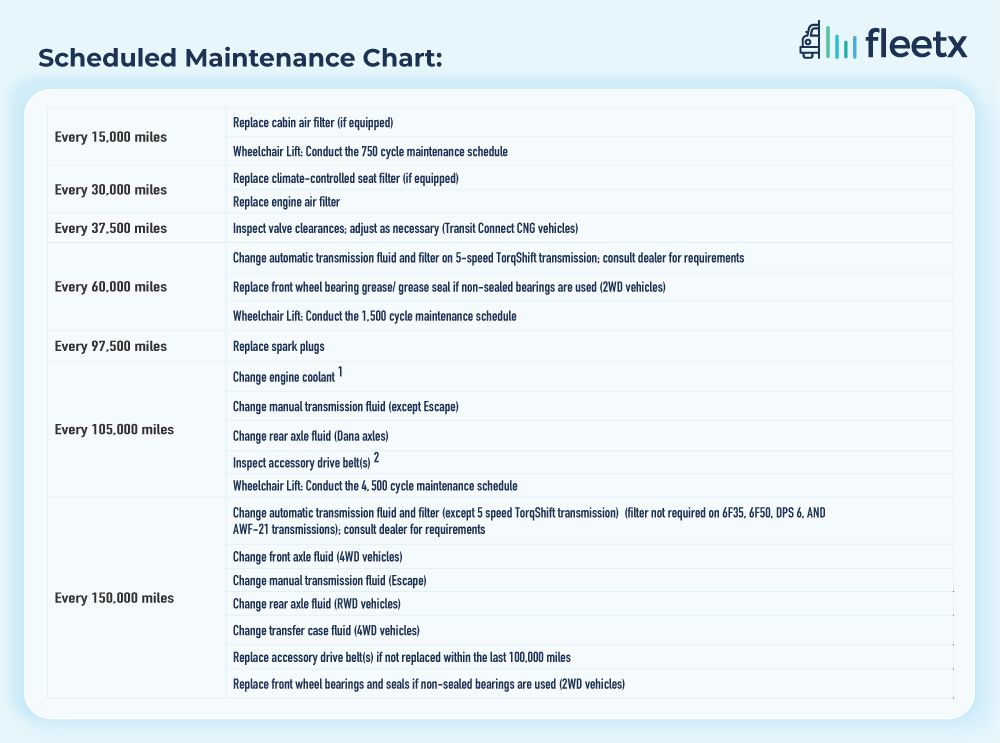

Maintenance Schedule: In the maintenance plan, a checklist for all preventive maintenance tasks related to the vehicles must be prepared. Service intervals, a section for drivers to file complaints, river inspection reports, an automotive facility where inspections, maintenance, and repairs will be performed, a staff of automotive technicians, a spare parts and inventory section, and a record-keeping method that includes documents should also be included.

Identify a Baseline: Have a comprehensive understanding of the current state of your fleet, do a thorough inspection of each vehicle, and have access to all vehicle information, including service and maintenance records.

Maintenance Intervals: Set the frequency of preventative maintenance for each kind of vehicle in your fleet. For several types of automobiles, maintenance schedules may differ, and depending on the type of vehicle, maintenance may be prompted by various circumstances. The operational circumstances may also affect your preventive maintenance periods. You must choose the metrics to track for each vehicle, such as miles, fuel consumption, operation hours, or other metrics, in order to successfully do preventative maintenance.

Software for preventive maintenance: Preventative maintenance software can greatly streamline the planning, organizing, and managing of fleet maintenance. Features including asset and vehicle monitoring, cost tracking, license tracking, work orders, insurance claim management, and customer/vendor portals should be included in the programme.

The programme ought to offer a dashboard that may group all of the tasks by category and subcategory. If certain duties are not completed, it should automatically reflect and give alerts. Work order, date, time, pending tasks, preventive tasks, km reading, and other components should be on the dashboard. Additionally, it should have spare parts and an inventory section that can indicate when an inventory is required.

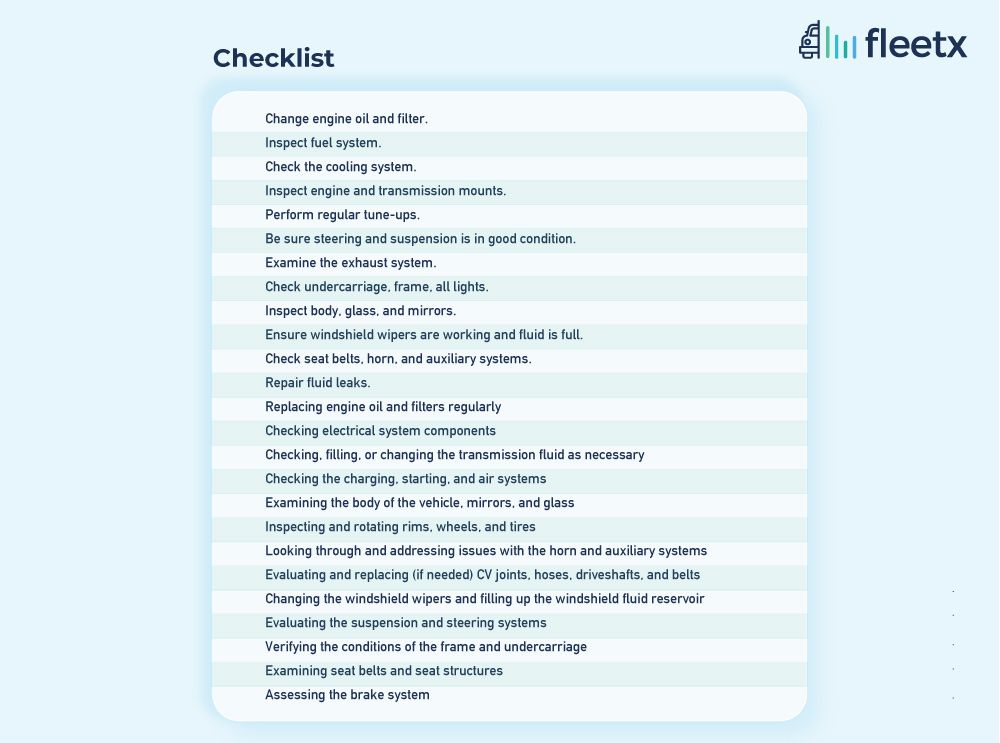

Checklist for preventive maintenance: The items in this list are some of the fundamental requirements for most vehicles:

Several things to keep in mind when creating a preventive maintenance checklist

Maintenance objectives: Know the maintenance objectives for your fleet. While some businesses prioritize lowering maintenance expenses, others are more concerned with increasing dependability and fuel efficiency. Others concentrate on both. According to the objective, the checklist should be prepared.

Vehicle types: The types of vehicles you maintain will frequently have an impact on the kind of maintenance jobs you plan as well as their maintenance frequency. All vehicles have various maintenance requirements.

Maintenance frequency: It's crucial to regularly maintain vehicles to keep them in good shape. To prevent emergency interruptions, maintenance should be carried out frequently rather than when there is a sudden requirement.

Vehicle checkup during downtime: Companies should be aware of the common reasons for vehicle failures/ breakdowns before organizing the full checklist so that they can be ready for them and handle them cost-effectively.

Federal and state laws: Federal and state regulations apply to many facets of fleet management, and frequently, those regulations will tell what you need to check for when inspecting your vehicles. Some laws even mandate routine inspections, to keep fleet vehicles safe, effective, and environmentally friendly.

Is PDI an important aspect of preventive maintenance?

When a fleet is purchased, it goes through vehicle PDI. Before entering, some general inspections are required, which determine whether the vehicle is in good condition. If the vehicle is purchased locally, then the chances for any defect are less, but if the vehicle or machine is imported, then transportation damages, missing parts, and scratches are possible because of the long route. All these causes can affect the vehicle and further call for heavy and expensive maintenance. Thus, a vehicle PDI is a must before purchasing any vehicle.

Before investing in new vehicles, fleet managers should prepare a checklist and double-check all the information. Though companies offer a thorough PDI report, fleet managers should check all the papers, components, licenses, and engines.

Conclusion

Any company that depends on vehicles must perform the crucial work of fleet management, that includes preventive maintenance. One of the most essential elements in maintaining a fleet that is trustworthy and safe is preventive maintenance. In addition to being crucial for maintaining vehicle compliance and safety regulations, periodic maintenance can also help the company run smoothly by saving time and money.

Safety is increased, breakdowns are avoided, future repair costs are reduced, and the company's reputation is enhanced by well maintained vehicles. The preventive maintenance services that each vehicle needs on a practical timeline will certainly be outlined in a fleet preventative maintenance programme, which can save a lot of unneeded costs. Thus, implementing a strict preventive maintenance programme is a must for companies that deal with fleets of vehicles.