Many industries, especially related to construction, logistics, and fleet management, are gravitating towards RFID technology to keep track of their vehicles, shipments, and equipment. With real-time location tracking, this technology is fast emerging as a necessity for companies that want to measure the efficiency of transportation and delivery operations.

RFID technology is used with fleet and logistics processes to track vehicle movement and manage shipments by ensuring managers know exactly where their location is. Apart from logistics and supply chain visibility, uses of RFID are also seen in retail and warehouse management as a way to streamline processes such as store-level inventory, checkout, in-store traffic patterns, theft detection, and more.

What is RFID ?

RFID stands for Radio Frequency Identification and is a part of the group of technologies known as AIDC or Automatic Identification and Data Capture. RFID technology works on radio waves that are used to send and receive information through a wireless non-contact manner to transfer data. This system is made up of two main components - a reader and a tag. These tags have an integrated circuit and antenna that are used for transmitting data to the RFID reader. The reader then converts these radio waves into a more understandable form of data that can later be analysed on a computer system. This collected information is transferred through a communications interface and is stored in a database on your system.

At its simplest level, RFID tags can be compared to barcodes in order to better understand how they work. Just like barcodes, RFID tags are very commonly used for trucks to monitor their location or track shipments. But since RFID tags work on radio wave technology, they don’t need to have a direct line-of-sight for the reader to scan them, unlike barcodes that need to be oriented in specific positions in front of a scanner. This means by using such technology, you can scan as many as 700 products each second as long as they are within the range of the reader.

Various types of RFID systems

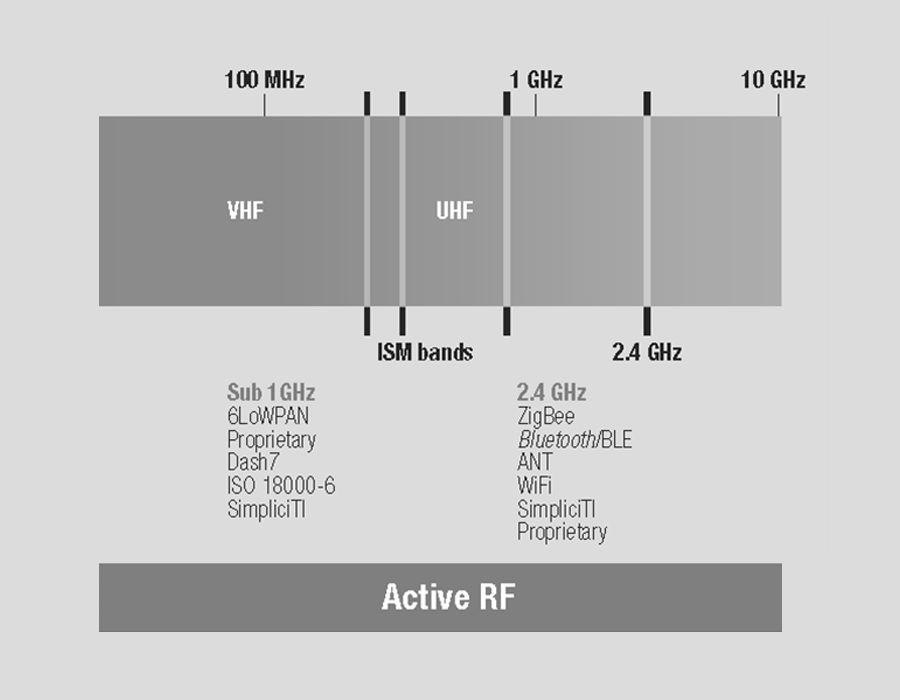

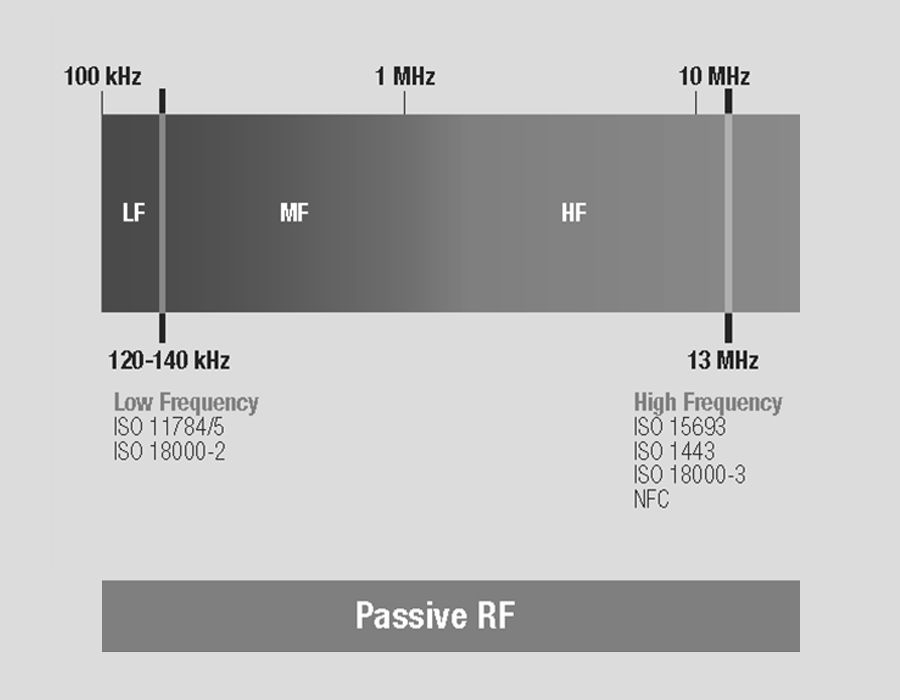

RFID systems are differentiated based on their frequency range - low, high, and ultra-high. Within each of these RFID types, they can either be active, passive, or battery-assisted passive.

Low frequency RFID systems

Low frequency (LF) RFID systems have slower read rates as well as a shorter range to read the tags as compared to the high and ultra-high frequency systems. They operate within the range of 30 kHz to 300 kHz and have a read range of around 10 cm. On the other hand, the advantage of using LF RFID systems is that they are less susceptible to liquid or metal interference due to their longer wavelength.

High frequency RFID systems

High frequency (HF) RFID systems have a bigger memory and come with a longer read range as opposed to low frequency RFID systems. These systems have a reading distance from 10 cm up to 1 m and operate between the range of 3 MHz and 30 MHz.

Ultra-high frequency RFID systems

Ultra-high frequency (UHF) RFID systems work between the frequency range of 300 MHz and 3 GHz and have a reading range that goes up to 12 m, thus offering extremely fast data transfer rates. This is also known as the “supply chain frequency” due to its vast range as well as a comparatively lower price than other types of RFID systems. This ultra-high frequency makes it very easy to read hundreds of tags at the same time, reducing the time and effort it would take earlier to carry out such a task. They are more susceptible to liquid or metal interference as well as electromagnetic signals than the other systems but advancement in IoT technology and new design innovations have mitigated some of these issues.

Active, passive, or battery-assisted passive RFID tags

Active RFID tags - Active RFID tags come with an included transmitter and power source and periodically transmit signals. These are usually ultra-high frequency RFID systems and can boost signal strength to extend read ranges up to 100 m in most cases. Due to these advanced capabilities, these tags are much bigger in size and costlier than others and are thus often used for high-value assets like construction equipment in fleet vehicles and such. They also come equipped with sensors that can track and measure several factors. Active tags are of two types - transponders that “wake up” only when they receive a signal, and beacons that emit a signal at certain pre-set intervals.

Passive RFID tags - Passive RFID tags stay dormant until a radio signal is received from a reader. This energy from the signal turns the tag on and then reflects information-carrying signals back to the reader. They have a shorter read range than active RFID tags, but are smaller in size and less expensive, making them more flexible for use.

Battery-assisted passive RFID tags - Also known as semi-passive RFID tags, these hybrid tags contain a battery and don’t transmit periodic signals as active ones do. Instead, their battery only turns the tag on upon receiving a signal, allowing the captured energy from the reader to be fully reflected back to elevate data transfer rates as well as improve read distance.

The need for RFID in fleet management is now

Radio Frequency Identification (RFID) is a key technology in the field of IoT and is undoubtedly a very essential component that helps enhance efficiency for businesses when it comes to areas such as fleet management or supply chain management. For instance, a main area where such a system comes handy is when vehicles need to get inside or outside the business premises. Gate-in and gate-out processes are much faster with RFID and don’t require manual verification each time a vehicle is at your gate. Such a system also offers several benefits like streamlined processes, cost control, maintenance, risk minimisation, transparency, fuel management, safety, tracking, as well as reliable user identification and access control. Such a robust system can help in maintaining driver and vehicle-related processes for long distances or short routes, ensuring that your fleet is running optimally at all times.

What does RFID stand for in trucking?

A proven data-carrying and automatic identifying technology used by industry is radio-frequency identification (RFID), which enables data to be broadcast from a miniature silicon chip at very high rates and without the need for line of sight, as required by barcodes.

How is RFID used in vehicle tracking?

Instead of providing continuous tracking like GPS can, RFID devices track vehicles from one location to the next. RFID, however, provides a number of benefits such as automatic recognition and recording, improved precision and dependability, and the capacity to function in enclosed or inside areas without a GPS signal.