The metal industry holds paramount importance in various sectors, serving as a foundational pillar for manufacturing, construction, and technology. Its products are integral to infrastructure development, transportation, and technological advancements. The industry's vitality is evident in its widespread applications, influencing economic growth and innovation on a global scale.

Supply chain disruptions pose significant threats to industries, particularly the metal sector. Prolonged delays or interruptions can hinder production, leading to increased costs and potential market share loss. A resilient and streamlined supply chain is imperative to maintain operational efficiency, meeting demand fluctuations and adapting to unforeseen circumstances. Effective supply chain management minimizes the impact of disruptions, safeguarding production timelines and ensuring consistent product availability.

From Raw Materials Procurement to Distribution

The metal supply chain is a multifaceted journey, intricately weaving through various stages from raw materials procurement to distribution. This complex process involves a delicate dance of strategic planning, risk management, and innovation to ensure a seamless flow that meets the demands of an ever-evolving market.

Raw Materials Procurement

At the genesis of the metal supply chain lies the critical phase of raw materials procurement. The challenges are manifold, ranging from fluctuating commodity prices and geopolitical tensions to environmental regulations. Industry players must strategically source raw materials, diversify suppliers to mitigate risks, and adopt real-time monitoring technologies for enhanced visibility into the procurement process.

Processing and Manufacturing

Once raw materials are secured, the journey continues through processing and manufacturing. Quality control measures are paramount, and stringent standards must be upheld to meet industry regulations. Long lead times and potential bottlenecks in the production phase necessitate meticulous planning to ensure a steady output that aligns with market demands.

Supply Chain Resilience

As the metal products move through the supply chain, resilience becomes a cornerstone. Supply chain disruptions, be they due to global events, transportation constraints, or unforeseen challenges, can have ripple effects. Robust risk management protocols, contingency plans, and the ability to adapt swiftly are crucial to maintaining operational efficiency.

Distribution Challenges

The final frontier of the metal supply chain involves distribution. Coordinating the transportation of finished goods to diverse markets introduces its own set of challenges. Efficient logistics, warehousing, and coordination with distributors are essential to ensure timely deliveries, prevent stockouts, and meet customer expectations.

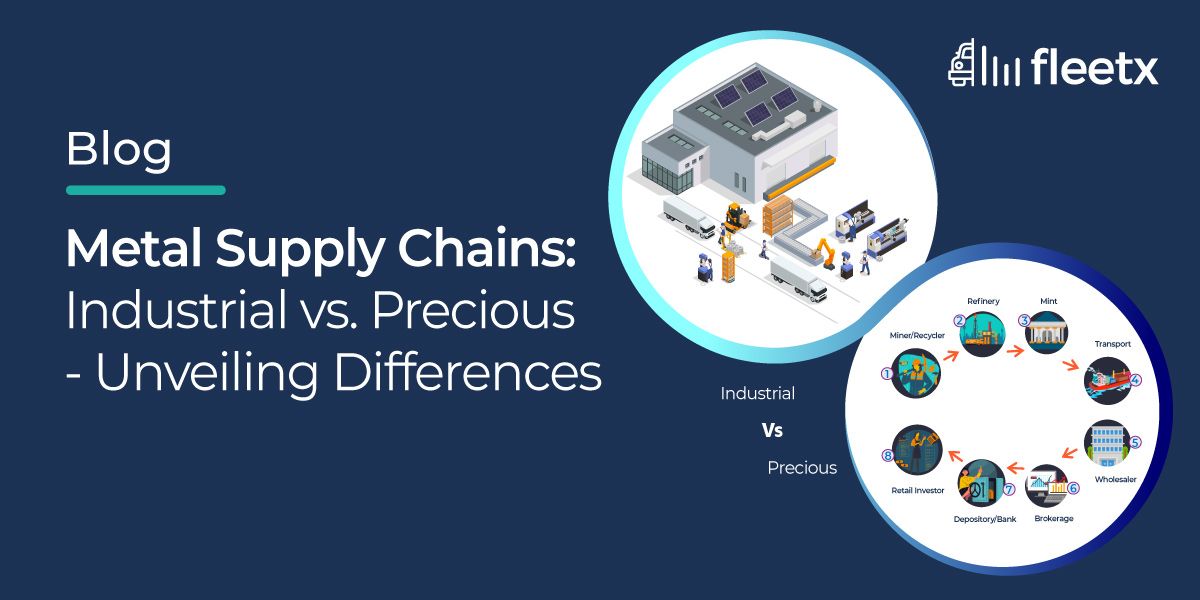

Industrial and Precious Metal Supply Chains

The supply chain complexities in the industrial and precious metals sectors add an intricate layer to the already intricate process of metal production. In the realm of industrial metals, such as steel and aluminum, the challenges stem from the sheer scale and volume of production. These metals are foundational to numerous industries, leading to extensive raw material procurement, intricate manufacturing processes, and intricate distribution networks. Variability in demand, coupled with global market dynamics, necessitates agile supply chain management to prevent bottlenecks and ensure a steady flow from production to distribution.

On the other hand, the precious metals sector, which includes gold, silver, and platinum, introduces unique challenges due to their scarcity and high intrinsic value. The procurement of precious metals often involves navigating geopolitical complexities, environmental regulations, and ethical sourcing considerations. Additionally, the intricate refining processes required to meet the stringent purity standards further contribute to the intricacies of the supply chain. The logistics of securing and transporting these valuable commodities demand heightened security measures.

Both industrial and precious metals share common challenges in terms of supply chain disruptions, quality control, and market volatility. However, the precious metals sector, with its added layer of rarity and value, requires an even more nuanced approach to procurement, processing, and distribution. Balancing these complexities in both sectors is crucial for maintaining the stability and resilience of the broader metal supply chain.

Key Challenges

- Market Volatility: Both sectors face price fluctuations driven by global events.

- Supply Chain Disruptions: Unforeseen events can disrupt the flow of raw materials and finished products.

- Quality Control and Compliance: Stringent standards and compliance with regulations are vital.

- Ethical and Environmental Considerations: Responsible sourcing is increasingly important.

Facing Challenges and the Need for Clear Vision

As we delve into the complexities of industrial and precious metal supply chains, the procurement of raw materials emerges as a critical juncture fraught with challenges. The shared obstacles of market volatility, supply chain disruptions, and stringent quality standards intensify when compounded by the scarcity or shortage of raw materials.

Challenges When There's Not Enough

So, imagine we can't get all the things we need to make stuff. Prices for these things can jump around a lot, our plans get messed up, and it's tougher to make sure everything we create is top-notch. Plus, it makes it harder to be ethical and environmentally friendly in how we get these materials when they're not easy to find.

Why It's a Big Deal

Now, when we don't have enough raw materials, it messes up the whole process. Making things takes longer, costs more money, and we might not be able to give people what they want. It's like a big chain reaction.

Visibility Makes a Difference

But here's the key - being able to see and understand what's happening at every step helps a lot. When we use cool technologies like blockchain and IoT, it's like turning on the lights in a dark room. We can see what's going on, fix problems quicker, and make smart decisions.

Conclusion

Real-time visibility stands as the linchpin of success. It operates as a strategic asset, akin to a precision tool in a craftsman's hands. The ability to monitor and comprehend every step of the process in real time equips businesses with the foresight needed to navigate challenges efficiently. This heightened visibility empowers timely decision-making, fosters proactive issue resolution, and streamlines the entire supply chain. In a professional context, it is not just a tool; it is a strategic advantage that enhances operational efficiency, mitigates risks, and ultimately ensures a responsive and adaptive approach to the dynamic demands of the industry.

Ready to Experience Our Product?

Book a demo today and discover how our product can benefit you.