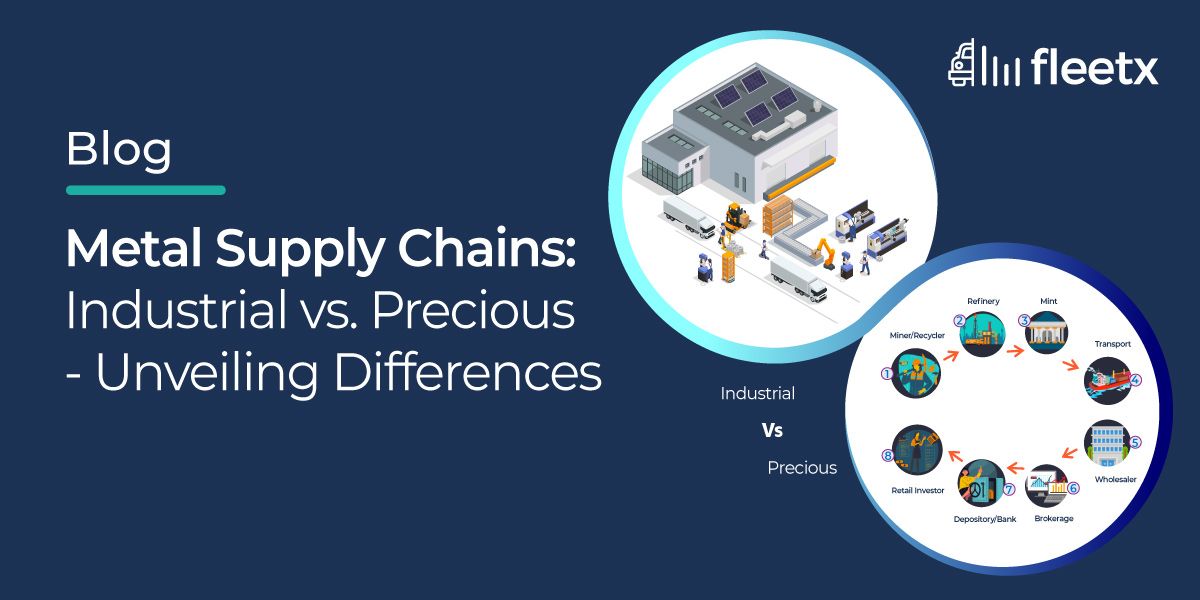

Distinguished by their markets, applications, and strategic importance, the metal supply chain and the precious metal supply chain offer distinct insights into the dynamics of modern industry. By dissecting these supply chains, we gain a deeper Supply Chain

Industrial Metal Supply Chain

The Industrial metal supply chain encompasses a diverse array of metals, spanning both ferrous (e.g., iron, steel) and non-ferrous (e.g., aluminum, copper, zinc) varieties. These metals serve as fundamental components across numerous industries, including construction, automotive, aerospace, electronics, and manufacturing. The supply chain orchestrates a series of intricate processes, including mining, refining, processing, manufacturing, distribution, and recycling.

Precious Metal Supply Chain

In contrast, the precious metal supply chain is focused exclusively on metals characterized by their rarity and high economic value. This category includes esteemed metals such as gold, silver, platinum, and palladium. With unique properties rendering them highly sought after, precious metals find application in jewelry, investment ventures, and specialized industrial sectors like electronics, catalytic converters, and medical devices.

The supply chain for precious metals mirrors that of the broader metal supply chain, encompassing mining, refining, processing, trading, and recycling. However, owing to their elevated value and limited availability, the handling of precious metals often necessitates heightened security measures and specialized protocols.

Furthermore, the dynamics of precious metal markets diverge from those of base metals, with prices intricately influenced by economic conditions, geopolitical factors, and investor sentiment.

Industrial Metal and Precious Metal Supply Chain Issues

Similar Challenges-

1. Environmental Impact: Both supply chains involve resource extraction processes that can have significant environmental consequences, such as habitat destruction, pollution, and depletion of natural resources. Sustainable practices and regulatory compliance are critical concerns.

2. Supply Chain Complexity: Both supply chains are complex, involving multiple stages from extraction or acquisition to processing, transportation, and distribution. Managing this complexity requires efficient coordination and logistics to ensure smooth operations.

3. Regulatory Compliance: Compliance with local, national, and international regulations is essential for both supply chains. Regulations may cover environmental protection, worker safety, labor practices, and product quality standards.

4. Technological Advancements: Embracing technological advancements is crucial for staying competitive and optimizing operations in both supply chains. This includes adopting automation, data analytics, IoT (Internet of Things), and other digital technologies to improve efficiency and productivity.

Different Challenges:

1. Material Characteristics: Precious metals, due to their high value and unique properties, may present challenges related to security, handling, and specialized processing techniques that differ from those encountered with base metals.

2. Market Volatility: Precious metal markets often exhibit higher volatility compared to base metal markets due to factors such as geopolitical tensions, currency fluctuations, and investor sentiment. This volatility can pose challenges for pricing, inventory management, and risk mitigation strategies.

3. Availability and Accessibility: Precious metals are generally rarer and more limited in availability compared to base metals. This scarcity can lead to challenges in securing a consistent supply, especially for niche applications or during periods of increased demand.

4. Value Chain Dynamics: The value chain dynamics in the precious metal supply chain may differ significantly from those in the base metal supply chain due to factors such as branding, certification, and market segmentation based on quality and purity standards.

Logistics Contrasts Between Precious Metal and Industrial Metal Supply Chains

The primary difference between logistics issues in the precious metal supply chain and the industrial metal supply chain lies in the nature of the materials involved and the specific challenges associated with their handling, transportation, and distribution.

Let's take a look at key differences

Precious Metal Supply Chain:

- Security Concerns: Precious metals, such as gold, silver, platinum, and palladium, are high-value commodities that are often targeted by thieves due to their intrinsic worth. Security measures throughout the supply chain, including armored transport and secure storage facilities, are paramount to mitigate the risk of theft.

- Supply Chain Transparency: Due to the high value and ethical considerations surrounding precious metals, there is a greater emphasis on transparency and traceability in the supply chain. Ensuring the ethical sourcing of precious metals and complying with regulations such as conflict minerals legislation requires robust documentation and supply chain transparency measures.

- Specialised Handling Requirements: Precious metals may have unique chemical properties that require specialised handling and storage conditions to prevent contamination or degradation. For example, platinum group metals (PGMs) are sensitive to impurities and require careful processing and handling.

Industrial Metal Supply Chain:

- Raw Material Sourcing: Industrial metals, such as iron, steel, aluminum, copper, and zinc, are typically sourced from mines or extraction sites worldwide. Logistics challenges in the industrial metal supply chain often revolve around sourcing raw materials from remote or politically unstable regions, leading to supply disruptions.

- Processing and Refining: Industrial metals undergo extensive processing and refining before they can be used in manufacturing. Logistics issues in this stage of the supply chain may include equipment failures, maintenance downtime, and transportation bottlenecks that impact production schedules and output.

- Inventory Management: Managing inventory levels of industrial metals is critical to meet demand fluctuations while minimizing carrying costs. Efficient logistics systems are needed to ensure the timely delivery of metals to manufacturing facilities and construction sites, preventing production delays.

In conclusion

While both the metal supply chain and the precious metal supply chain share common challenges such as environmental impact, regulatory compliance, and technological advancements, their logistics issues differ based on the materials involved and their handling requirements.

The precious metal supply chain demands heightened security measures and transparency due to the high value and ethical considerations associated with these metals, while the industrial metal supply chain faces challenges related to raw material sourcing, processing, and inventory management to meet manufacturing demands.

By understanding and addressing these logistics contrasts, stakeholders can develop tailored strategies to optimize supply chain operations and ensure the efficient flow of materials through both sectors of the industry.