Picking up the baton from where we left off in our previous article on how TMS can improve transportation for pharma companies, we will now delve deeper into how pharma companies manage their day-to-day operations related to transportation. Pharma companies that rely on own-manufacturing typically do not differ significantly from one another when it comes to their transport operations. However, upon closer assessment, they incorporate a mix-and-match of different TORs (Terms of Agreement) for drug manufacturing and distribution. This can include own manufacturing units, third-party manufacturers, as well as loan liaising companies. Another key difference between drugs produced from own-manufacturing and third-party manufactured drugs is observed during distribution. Drugs produced from own-manufacturing can go directly to the CFA, followed by Super stockist and so on, or go to a central warehousing from where they are processed further. Meanwhile, drugs produced by third-party manufacturers have to go to the central warehousing from where they are processed further down the distribution channel.

After educating ourselves on the nuances of pharma manufacturing, it is natural to wonder how pharma manufacturing companies manage their procurement, accounting, and everything in between. Well, pharmaceutical manufacturers use one version or another of an Enterprise Resource Planning or ERP software that helps businesses control, connect, and integrate all departments and internal processes. This software automates all key functions, such as planning, procurement, inventory, manufacturing, and business intelligence. Over the past 20 years, ERP has been omnipresent across all manufacturing operations, including pharmaceuticals manufacturing. However, adoption of automation tools, such as enterprise transport management solutions, has been relatively dismal. Technology integration in enterprise logistics and transport operations can help businesses improve operating efficiency and reduce cost. For pharma companies, more supply chain visibility and real-time monitoring solutions, such as cold chain fleet management solutions, can make transporting temperature-sensitive drugs and vaccines safer and more convenient. Leading by example, several companies now tend to set up digital budgets to digitize their transport and logistics operations end-to-end.

Key challenges faced by businesses during logistics or transport planning

Perhaps the biggest challenge faced by pharma businesses in their logistics and transport operations is planning. Logistics or transport planning has three rudimentary questions, so to speak:

- How many trucks are required?

- What kind of trucks are required?

- How can the loads be consolidated together?

The primary reason for these questions is to ensure that the cargo is shipped quickly and at the lowest cost.

How is a TMS integrated with logistics or transportation planning?

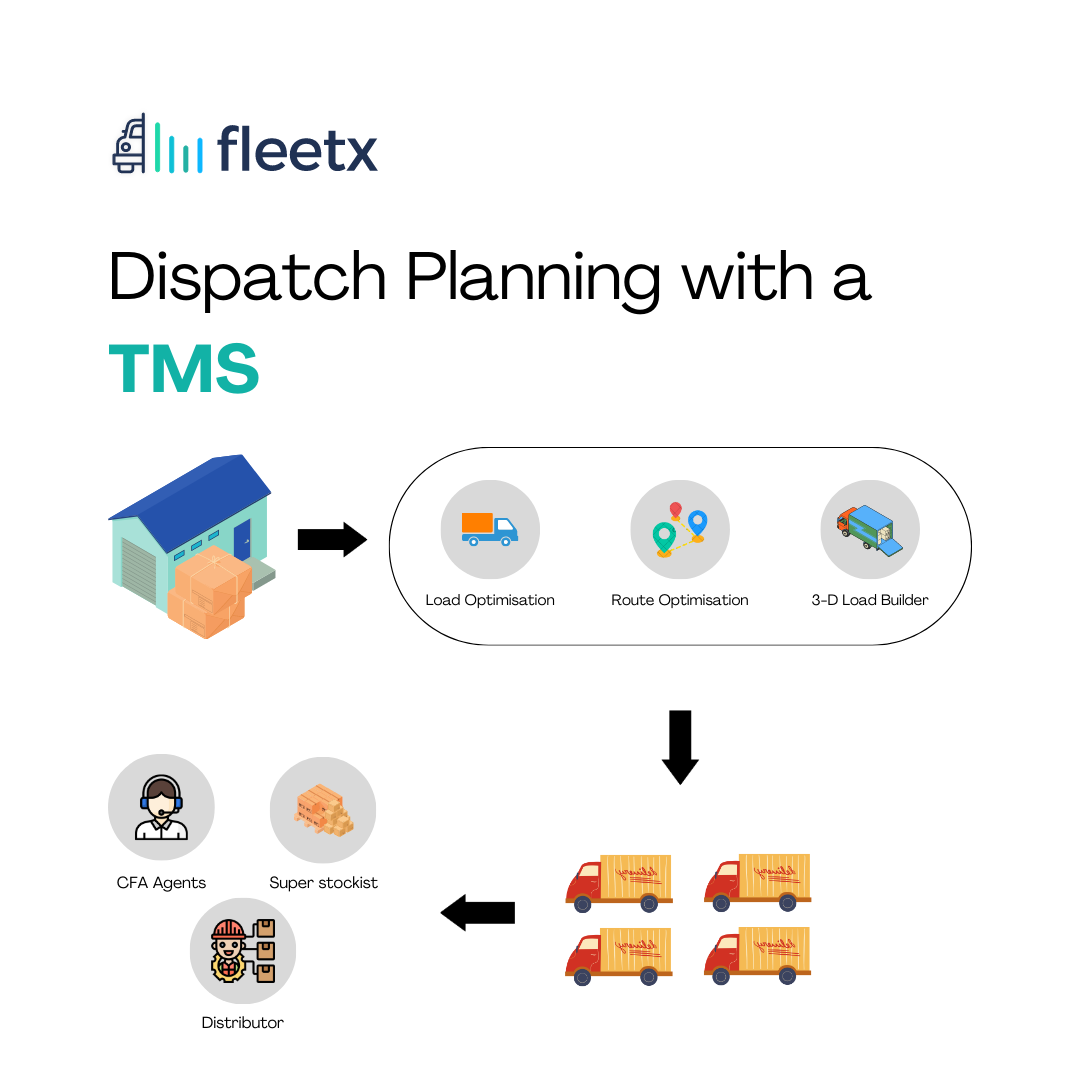

The role of the Transport Management System or TMS in logistics or transportation planning in the pharma industry can be understood through the process of dispatch planning, which can be broken down into three parts:

Load Planning/Optimization

An optimizer is an essential tool that can deliver significantly better results compared to manual planning. For instance, if a company's transportation operations require 100 trucks per month based on cargo load, an optimizer can help reduce the number to 85-90 trucks per month, resulting in cost savings

Route Planning/Optimization

The route planning step essentially involves the consolidation of the cargo load. For example, suppose a manufacturing unit is based in Kolkata and needs to deliver three shipments to Prayagraj, Delhi, and Amritsar, respectively. In that case, instead of engaging three trucks for three separate routes from the base location of Kolkata, a route planning module will predict that all these locations fall on the same highway (NH-19). Thus, it would consolidate the load and use one truck instead of three. In essence, the route planning module helps companies reduce costs by ensuring the maximum utilization of resources.

Pharma companies tend to have a much wider distribution network, from their own-manufacturing to third-party manufacturing to other stakeholders down the distribution channel. The application of route planning is most suited for last-mile deliveries. However, most pharma manufacturers do not manage last-mile delivery on their own. Instead, they rely on FMCG companies, as their channel partners are often the same.

3-D Load Builder

The third module is the 3-D load builder, which essentially instructs on how to load goods into trucks to ensure maximum resource utilization. For instance, during multi-point deliveries by goods carrying trucks, if the cargo required to be delivered at the first point is loaded at the end of the truck, the truck will have to unload all other cargo intended for other locations before unloading the cargo meant for the first location. Transport operations managed in this way result in a waste of time, labor, and risk damaging other goods loaded on the same truck.

In the case of sensitive pharmaceutical goods, the risk becomes even higher.

In such cases, a 3-D load builder helps companies load the cargo in a way that ensures maximum efficiency with zero errors. A 3-D load builder assists pharma companies by ensuring that all stacking and packaging norms and compliances are followed while loading the goods.

The best part?

3-D load builders provide a pictorial representation that is easy to understand and implement across warehouses and manufacturing facilities.

Learning by example: Why dispatch planning in TMS matters

Dispatch planning is arguably the most critical component of a Transport Management System (TMS). To underscore this point, let's review the three different TMS modules together. By doing so, we can gain a deeper appreciation for how adopting a TMS can benefit your pharmaceutical company's logistics and transportation operations.Let's consider a pharmaceutical company that operates its own manufacturing unit in Kolkata while also collaborating with third-party manufacturers from Tamil Nadu and Telangana.

This company primarily serves super stockists and distributors in North India. By using a TMS to plan and execute the transportation of goods from manufacturing to delivery, they can maximize efficiency and reduce costs significantly. The TMS optimizes truck requirements based on orders and plans routes to ensure maximum efficiency in delivering goods to customers through multi-point deliveries.

Additionally, the route planning software ensures drugs are delivered to customers from the closest manufacturing plant using the shortest and most efficient route. Finally, the 3-D load builder ensures goods are loaded in delivery trucks safely, leading to maximum resource optimization.

In a nutshell

Upon reading this, an obvious response could be that everything we talked about can also be done manually. As a matter of fact, it can. However, the scale at which most pharma companies operate involves thousands of orders to transport several tons of goods across hundreds of locations. Medium-sized pharma companies utilize hundreds of trucks in a given month, while large-scale companies could require thousands of trucks as well. Therefore, the question you should ask yourself before getting a TMS is whether your company would like to conduct transport operations at such a scale manually, which would increase the chance of errors exponentially. In a nutshell, a TMS would primarily automate the transport/dispatch planning and execution, maximizing the efficiency of the entire operation while bringing down the cost of transportation.