The Indian subcontinent is one of the most resource rich regions in the world with resources clustered in pockets all over the country. Some of the major mineral reserves in India include Coal, Iron Ore, Bauxite, Mica, and Limestone among others. Certain states in India have a much larger congregation of mines compared to others due to their rich geology. For example, Odisha, Andhra Pradesh, Rajasthan, Chhattisgarh, Jharkhand, Madhya Pradesh and Karnataka have the highest accumulation of mine wealth with the most number of active mines. As of 2020, the state of Odisha has over 243 mines that are rich in minerals and metals such as high-grade Iron ore, Bauxite, Chromite, and Manganese ore, among other minerals like coal, limestone, dolomite, diamond, etc.

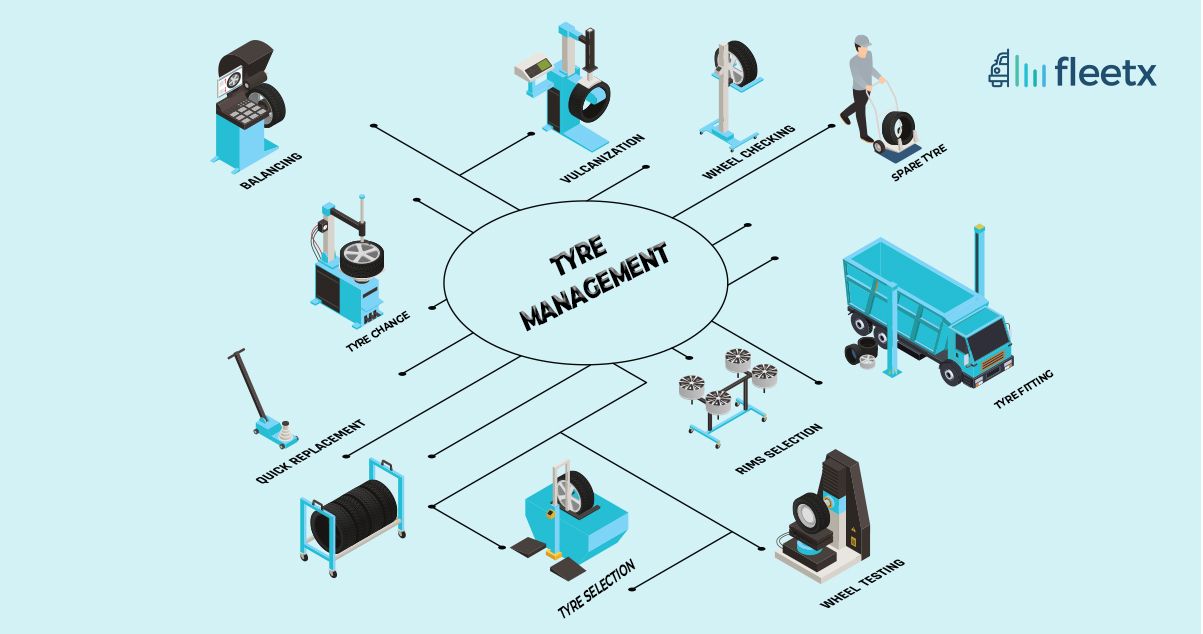

On the surface, tyre management sounds pretty simple: keeping track of the wear and tear of your vehicle's tyres and replacing them when it's too worn out. However, tyre management can be quite complex depending on the type of vehicle and the industry. Furthermore, successful tyre management can yield many benefits for your fleet, such as reducing maintenance costs and increasing operating efficiency.

Equipment and vehicles used in different industries to carry out operations are fitted with tyres designed based on the usage and requirements to maximise their life. Heavy-duty equipment and vehicles are mostly employed in sectors like construction and mining and are typically called earthmoving vehicles and equipment as they involve a lot of earthworks. Focusing on the mining industry, earthmoving vehicles and equipment such as mining drill rigs, mining haul trucks and loaders, mining cars, draglines, and motor graders, among others, use various types of wheels, tracks and tyres to navigate and operate through the uneven and rugged terrains in and around mines.

The surface and surroundings on which the vehicles and equipment operate in mines may change depending on the mining activity. However, the wheels and tyres typically employed in the mining sector must meet certain basic requirements such as long durability and life, puncture resistance, high-speed operations and less frequent maintenance. To ensure these requirements are met, tyre companies continue to improve their offering for tyres fitted in vehicles and equipment used in mines. For example, Apollo Tyres recently introduced two new types of mining tyres that claim to reduce vehicle downtimes and offer much superior performance qualities and durability. The tyres are more suited for mining operations as there is limited exposure to rugged and rough terrains and typical operating conditions in and around mines.

Mining operations are crucial for the economy as they provide crucial resources and metals needed to sustain development. However, due to record-breaking inflation, companies across industries are forced to rethink operations and focus on improving efficiency while reducing operating costs. Thus, opting for more durable tyres would help businesses reduce costs as well as downtime for their vehicles and equipment.

Key characteristics of mining tyres

Tyre health is one of the most crucial metrics to measure the overall health of the vehicle or equipment, and the case of earthmover tyres, such as mining tyres, is no different. The conditions under mining operations require the vehicle tyres to possess certain characteristics, some of which are listed below.

- Mining tyres must have high load-carrying capacity since the vehicles frequently carry heavy loads operating in difficult terrain.

- Mining tyres are required to have high durability and exhibit reduced wear compared to other tyres.

- Mining tyres must be extremely resilient to cuts as they often operate on uneven surfaces, particularly in underground mines. Frequent cuts could halt and negatively affect the operation due to limited space available in and around mines.

- Mining tyres are also subjected to heat, which affects the tyre's health. Thus, mining tyres are required to run much cooler than other vehicles.

Among several other characteristics, mining tyres must have much lower contact pressure due to their frequent heavy load. The inability to have lower contact pressure would significantly increase the tyres' chances of busting.

Frequent causes of damage in mining tyres

Several practices increase the risk of damage to the tyres and negatively affect the overall operation in the mining industry. One of the most frequently reported ones is vehicle overloading, a common problem plaguing commercial vehicles across industries in India.

- Overloading vehicles, particularly trucks, can cause an unwanted rise in tyre temperature, weakening tyre structure and flexing, resulting in early scrapping of tyres despite showing little visible signs of damage or wear.

- Under-inflation of tyres can have a detrimental impact on the health of mining tyres as it limits the ability of tyres to bear the load correctly and causes fatigue and heat build-up due to excessive flexing on the sidewalls. In contrast, over-inflation of mining tyres inflicts structural damage to tyres due to poor load distribution making the tyres vulnerable to decreased resistance, cuts and wear.

- Excessive speeding can also lead to early wear and tear in mining tyres due to increasing heat build-up, leading to irreversible damage to the overall tyre structure.

Lastly, poor vehicle maintenance and improper use of equipment and vehicles also contribute to tyres' deteriorating health, resulting in premature wear and tear.

Conclusion

Due to the nature of operations, tyre health is of paramount importance when it comes to mining tyres. Thus, businesses must put effective measures in place to ensure all measures to improve mining tyre health are in place and effectively implemented by their workforce.

In addition, businesses can employ effective fleet maintenance softwares and

utilise other tyre management solutions to monitor the parameters such as tyre pressure and overloading in their operations to increase tyre health for their fleet, thus, bringing down maintenance costs and improving operating efficiency.

What is tyre maintenance?

In Tyre maintenance tread depth analysis, pressure analysis are primary indicators of tyre performance. Every fleet manager or Transporter have different checklist as per their need.

How to increase mining tyre life with tyre maintenance?

Mining tyres or OTR (Off the road tyres) are costly affairs, taking force into account, moderate speed and braking during harsh weather conditions can increase the life of Mining tyres.