AI dashcams are rapidly becoming standard in heavy-truck fleets. Their ability to monitor driver behavior, detect hazards, and record incidents gives trucking businesses a big advantage. But construction fleets don’t operate like highway trucks. Rough terrain, blind zones, site hazards, slow maneuvers, and multi-angle visibility needs - demand a more specialized dashcam approach. Let’s examine what distinguishes truck AI dashcams from construction equipment dashcams and why construction equipment fleets should steer clear of the one-size-fits-all approach.

Why is Safety a Priority in the Construction Industry?

Life, Liability, and Costs: If a machine hits a person or structure, the consequences are steep.

In construction operations, vehicles move amid workers, materials, unstable ground, and shifting site geometry. A misjudged swing of an excavator or an unseen worker walking into a blind zone can result in serious injury, project delays, insurance claims, fines, and reputational damage. Safety here is not optional - it’s mission-critical. For example, in India, there are ~38 fatal accidents per day in the construction sector, amounting to over 11,000 deaths annually.

Are AI Dashcams for Trucks Effective in the Construction Fleets?

Short answer: not reliably. Truck-geared AI dashcams are optimized for highway conditions - long straight stretches, consistent speeds, lane markings, and standard distances to preceding vehicles. In a construction environment, where motion is slow, stops and starts are frequent, obstacles are unpredictable, and visibility obstacles abundant, those models frequently misfire. Alerts about “lane departure” or “forward collision” become noise. The camera framing, angle, event triggers, and sensitivity thresholds - these are mismatched. In practice, you’ll see many false alerts, blind-spot misses, and missed incidents. That not only wastes your monitoring resources, but also leads to ignoring alerts entirely (e.g. - alert fatigue). In short, don’t expect a truck dashcam to substitute for a construction-grade dashcam.

Benefits of Construction Fleet Dashcams

Below are seven benefits of deploying AI dashcams designed for construction fleets:

- Real-Time Hazard Alerts — The camera detects people, tools, and machinery around the vehicle and warns the operator in real time, preventing collisions.

- Driver Behavior Monitoring — It tracks distracted actions (phone use, lack of seatbelt, fatigue) and issues in-cab alerts to correct behavior on the spot.

- Multi-Angle/Dual Views — Simultaneous front, rear, side, or interior views ensure no blind zone goes unmonitored.

- Incident Snapshot & Triggered Recording — When a threshold (impact, proximity) is exceeded, snapshots or clips are locked and flagged for investigation.

- Video & Telematics Integration — The dashcam integrates data (speed, GPS, accelerometer) with video to contextualize events and support root-cause analysis.

- On-Demand Video Retrieval — Managers can quickly pull specific time windows, events, or camera angles to inspect anomalies.

- Insurance & Liability Shielding — Clear timestamped video helps defend your fleet against false claims, accelerates claims resolution, and can reduce premiums.

These benefits combine into safer worksites, disciplined operators, lower claims, and stronger project continuity.

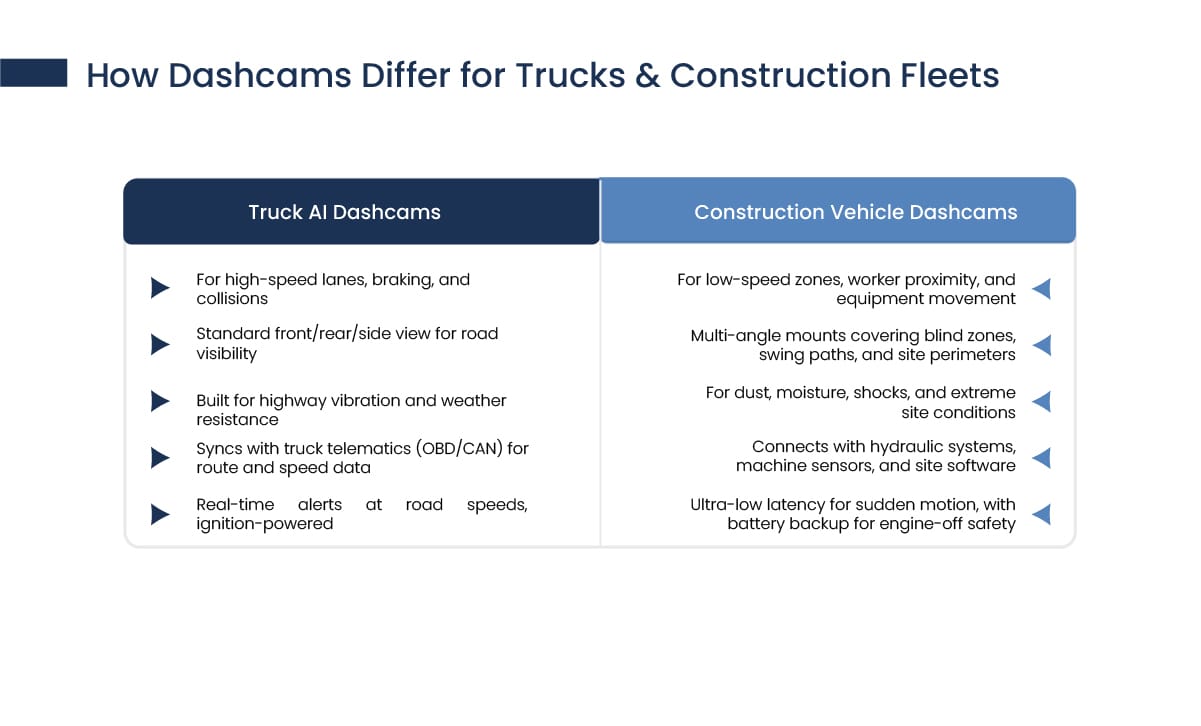

Truck AI Dashcams vs Construction Vehicle Dashcams

These distinctions make it clear: borrowing a truck dashcam for construction machines is like using a road camera inside a mine—it won’t perform.

Essential Features of Construction Work Dashcams

High-precision proximity detection — To sense movement of workers, materials, or tools near machine arms or buckets beyond human line of sight.

360°/multi-angle coverage — Surrounding views to capture all sides of the machine, especially rear and swing arcs.

Low-latency in-cab alerts — Instant feedback to operators to halt or correct before impact.

Event-locking & buffer retention — Pre/post buffer capture, event locking, multi-camera sync.

Rugged hardware & environmental tolerance — High IP ratings (dust, moisture), vibration damping, thermal range support.

Edge AI & video/telemetry fusion — On-device intelligence fusing sensor data (gyro, accelerometer, CAN bus) with video to minimize false alarms.

Remote monitoring & live view — Ability for supervisors to see views in real-time, send instructions, or flag issues remotely.

Seamless integration with fleet/site software — Capability to push data to your fleet management, project control, or safety software.

Backup power & failsafe recording — Recording continuity even if vehicle power fails (e.g., backup battery or supercapacitor).

Scalable firmware/OTA updates — Ability to deploy new detection models or calibrations over the air without physical replacement.

These features ensure the dashcam system is truly a site safety tool, not just a passive recorder.

Building Safety Intelligence: Why Construction Machines Demand Smarter Dashcams

Truck AI dashcams bring value on the highway, but fall short in construction environments. Construction fleet operators must assess dashcams through a site lens - not a highway lens. When correctly designed for slow-speed detection, blind zones, multi-angle coverage, ruggedness, and real-time alerts, AI dashcams become powerful co-pilots in preventing accidents, reducing costs, and protecting lives.

As the AI dashcam market expands (projected growth from USD 2.6 billion in 2024 at CAGR ~34 %) and video telematics grow at ~17.9 % CAGR, construction fleets need to demand fit-for-purpose solutions—not repurposed truck cams. For a construction site fleet, the right dashcam is more than a camera—it’s your second set of eyes, automated watchdog, and evidence vault all in one.

Can a standard truck AI dashcam be used in a construction vehicle?

Not effectively. Truck dashcams are built for highway conditions - steady speeds, visible lanes, and predictable traffic. Construction vehicles operate in rough, low-speed environments surrounded by workers and obstacles. A truck dashcam will misinterpret site activity as hazards or fail to detect actual dangers. Construction-specific dashcams are calibrated for these variables, offering better accuracy and fewer false alerts.

What makes a construction-grade AI dashcam different from a regular one?

Construction dashcams have multi-angle coverage, proximity sensors, rugged housings, and low-latency alerts. They’re designed to withstand dust, vibration, and temperature extremes while detecting people and objects in tight spaces. They also integrate with telematics and machinery systems - something most truck dashcams cannot do.

How do AI dashcams improve site safety and project efficiency?

AI dashcams act as real-time co-pilots. They detect unsafe behavior, monitor operator fatigue, alert workers in danger zones, and record every movement around heavy machines. This leads to fewer collisions, faster incident resolution, and stronger compliance with safety standards.

What should I look for when choosing dashcams for my construction fleet?

Focus on ruggedness, 360° visibility, AI-powered object detection, low latency, and seamless integration with your existing fleet software. Ensure they support multi-camera feeds, event locking, and over-the-air updates. Above all, choose hardware rated for heavy-duty, off-road use - not a modified truck solution