The chain of supply chain functions, globally, starts with Inbound logistics. It is the foundational pillar in the production cycle and optimization efforts are ongoing. Varied obstacles arise in the process of receiving, moving, and storing raw materials and components that are essential for the production of goods or rendering services, covering sectors such as:

- Manufacturing

- Retail

- Construction

- Healthcare

Let’s explore the scope of inbound logistics, the associated challenges, and ways to manage those. Technology has played a crucial role in transforming other sectors and here we’ll discuss its transformative potential in inbound functions.

What is Inbound Logistics - The Core Components

There are multiple stages involved in the inbound logistics system, some of which are:

Material Sourcing

Identifying and selecting the material supplier with competitive rates and suitable delivery terms is one of the most significant parts of the process. The quality of the materials determines the quality of the finished goods.

Purchase Transactions

The raw material purchase involves suppliers’ purchase agreement negotiations that include pricing, delivery timelines, and agreeing on the terms of payment.

Materials Transportation

This stage is all about coordinating the movement of goods from one point to another, commonly from the suppliers to the manufacturer’s warehouses or production facilities. The process requires working with shipment carriers, brokers, and other logistics stakeholders to ensure timebound and cost-effective deliveries.

Storage Facilities

Different categories of materials require several forms of organization and storage means for their most optimum utility in production. Temperature, hygiene measures, available storage capacity, packing material, etc. are essential considerations at this stage.

Quality Assurance

Before being used in production, the materials have to be inspected upon receipt to verify their compliance with the industry standards in the next stages.

Through effective management of these activities, businesses can save on costs incurred, enhance visibility into the supply chain functions, and improve their market competitiveness.

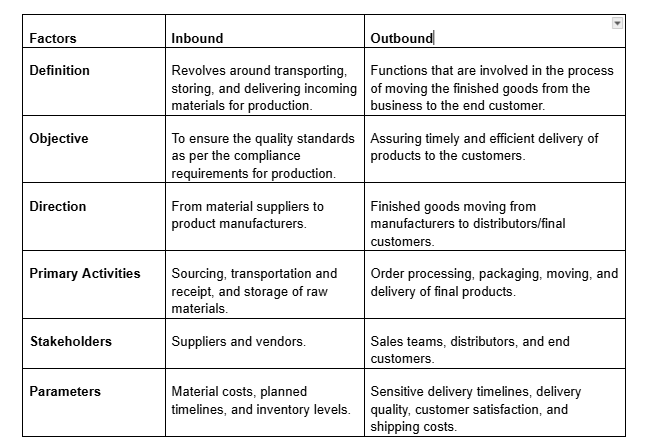

Broad Differences Between Inbound and Outbound Logistics

Inbound and outbound are two entirely different divisions in logistics operations. The functional differences are:

Both processes are independent of one another yet, are essential to ensure the efficiency and competitiveness of the overall supply chain.

Role of Inbound Logistics in Production

Let’s consider a cement manufacturer’s operations. They would require several raw materials, the basics being:

- Limestone

- Clay or shale

- Pozzolans

- Iron ore

- Gypsum

- Fly ash

Ordering lesser volumes of materials would hamper production, and higher order volumes would create stagnant inventory levels leading to higher costs. So, optimizing inbound logistics management results in the timely availability of the required materials in adequate quantities, optimizing costs and business profits.

Challenges in Inbound Logistics

Logistics comprises a wide variety of challenges and those associated with the inbound process are:

Transportation Hurdles

Multiple situations can lead to dysfunctional shipment schedules – unavailability of vehicles, natural calamities, vehicle breakdowns, and unplanned route diversions, are some.

Insufficient Visibility

Lack of supervision into inbound functions increases risks of accidents or thefts, idling, and route-related violations, leading to untimely delivery and inadequate quantities, ultimately causing financial business losses.

Improper Unloading Practices

Long queues outside and within the plant gates are common sights, leading to delays and goods damage, and ultimately the outbound operations.

Communication Shortcomings

The involvement of multiple stakeholders and the unavailability of a centralized communication platform breaks the efficient flow of information related to delivery progress, bottlenecks, costs, and more.

Increasing Costs

The inbound costs rise significantly due to various factors that include unplanned route diversions, and vehicle idling, among other factors that make inbound processes an expensive affair.

Businesses require updated and cost-effective visibility solutions to monitor the detailed aspects of the entire process and solve inefficiencies.

How to Improve Inbound Logistics with the Power of AI?

At Fleetx, our 7+ years of industry experience have enabled us to get a clear picture of the logistics landscape. Our constant problem-solving outlook has equipped us to innovate more efficient, transparent, and responsive solutions using artificial intelligence (AI) and has fueled us to develop inbound logistics best practices.

Planning & Visibility

The integrated and unified Transportation Management platform (TMS) manages end-to-end freight movement, addressing the issues of higher freight cost, inefficient planning, lack of visibility into the freight movement, and unavailability of an automated, centralized platform.

Contracts Management

Digital contract management is the nerve center for tracking and monitoring all transactional SLAs and is ideal for conducting freight audits. Such centralization of all contracts manages the complete lifecycle while recording and tracking the history of all changes implemented.

Spot Auction

An automated, negotiation-free process that saves valuable time by conducting auctions, receiving bids, and sending indents via WhatsApp for quick and easy communication.

Dispatch Planning

A route optimization tool to optimize transportation and reduce costs based on factors such as distance, on-road traffic, and others. Load planner optimizes the vehicle space utilization and multi-point unloading of the goods.

Vehicle Indenting

Transporters can send vehicle requisitions digitally and collaboratively, with ready visibility into each transporter’s share of the business and reporting ETA at origin.

Digital Proof of Delivery

The consignee can easily capture the real-time condition of the goods and also trace the FTL and PTL shipments and manage detentions through auto-capturing of truck entry and exit times. These automated features are crucial in ensuring a seamless freight settlement.

Inbound Logistics Optimization - How is Fleetx Control Tower Making a Difference?

One of the core aspects of the Fleetx software is the virtual tracking capability. The capabilities include:

● The virtual control tower monitors each trip against the contract SLAs

● Single interface to view all FTL & PTL shipments in transit

● View and manage all deviations and escalations easily at origin, in transit, and destination

● Auto application of SLA parameters on freight invoices

Optimize Inbound Logistics with Futuristic Solutions: Partner with Fleetx

A growing business’ reliance on technology is not a mere trend but a vital necessity. A technology-driven approach enhances accuracy and speed, thereby maximizing customer satisfaction. In the modern competitive marketplace, keeping the customers satisfied and engaged is the key to long-term success.

Fleetx’s AI-driven solutions have been significantly successful in redefining the inbound logistics landscape in India. Our clients have achieved a more advanced, efficient, and sustainable logistics framework, resulting in overall business success.