There is no doubt that time is money for any business, and when coupled with cost and resource savings, it becomes the ultimate holy grail that every business aims to achieve. So far, we have learned how a transportation management system (TMS) can deliver on all fronts of saving time, cost, and resources for pharmaceutical companies, specifically in terms of dispatch planning and management. However, despite the benefits it offers, the acceptance rate of TMS in pharma transport operations has been nearly absent.

In contrast, the fast-moving consumer goods (FMCG) industry, which also serves as a last-mile delivery partner to pharma manufacturers, has been at the forefront of TMS adoption in India.

Tackling the reluctance to adopt TMS in transport operations

Naturally, one might ask why businesses are reluctant to adopt TMS if it is such a good system. In this regard, it is important to note that India has historically been slow to adopt new technologies, preferring manual methods instead. Thus, it is natural for this reluctance to spill over into business decisions.

However, the winds have been changing due to several technology-driven startups that have disrupted the transport and logistics sector. Their success stories have provided enough case studies and reference cases for more traditional businesses to adopt technologies like TMS. This revolution has spawned several fleet management companies that serve as intermediaries, helping businesses across industries adopt technology solutions like TMS into their operations.

How can your pharma business adopt TMS effectively?

Another important topic that is often overlooked is the streamlining of business processes and operations. For example, if you do not know the quantity of dispatch, how can you plan the quantity of raw material that your manufacturing plant or business needs to procure? Delays in dispatching on-time or in-full can lead to warehousing or stocking issues at the central warehouse level or manufacturing plant level.

Storage issues at your warehouse or plant can affect raw material supplies due to limited availability of space, especially in cases where raw materials and packaging materials are being lifted from suppliers ex-work rather than on a landing cost basis. Therefore, it is important to ensure that both the inflow and outflow of raw materials are in sync, and a TMS can effectively help you achieve synchronisation between inbound and outbound logistics.

Certain processes that may seem marginally small or redundant on paper can create issues when everything needs to be done digitally. Therefore, it is essential for businesses to properly map out, streamline, and implement their logistics and transport operations in a TMS. Lastly, as we have discussed over the last two articles, the adoption of TMS remains a challenge, and companies across the industry are currently in the transition phase, implementing TMS in their transport operations in a phased manner.

Other factors for pharma companies to consider a TMS

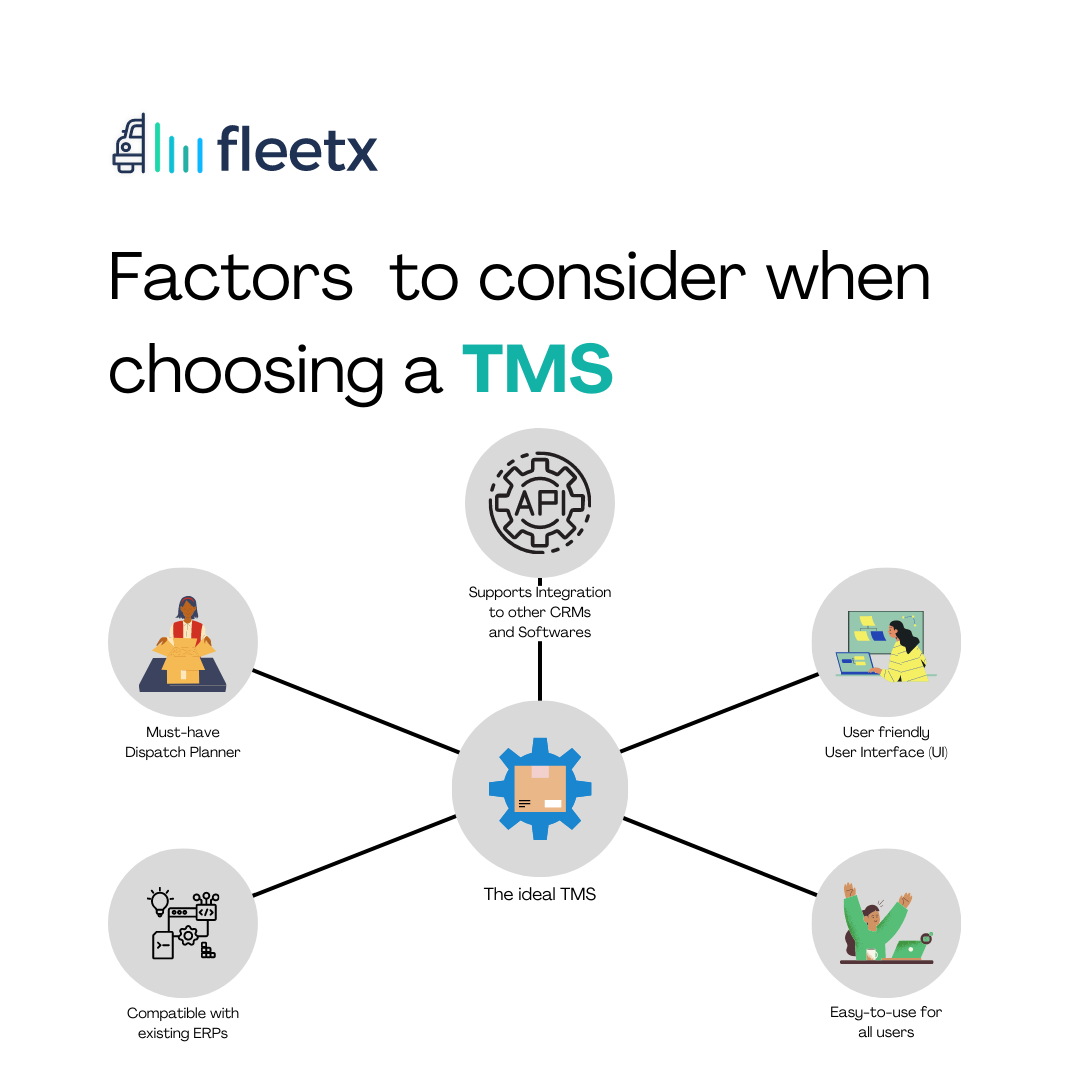

Training the workforce on TMS is an important factor that determines the willingness to adopt a new technology or process. Therefore, your company needs to be deeply involved in the transition process. However, the TMS offering also needs to be easy-to-use and provide seamless integration with existing ERP systems used by companies to input data into the TMS software. Compatibility with a wide range of ERPs or CRMs and ease-of-access are also some of the most critical criteria businesses need to consider when choosing a TMS software. Other criteria include a customer-friendly user interface, easy integration with other software, a good dispatch planner, and more.

In a nutshell

Several companies and organisations across the country offer technology-based solutions for businesses and enterprises. One of the most popular tech-based solutions today is the Transport Management System or TMS. The pharma industry has its own unique set of challenges and ways of managing transport that may differ significantly from other industries.

As a pharma company, you need a detailed and precise understanding of every aspect of your company’s transport and logistics operations before purchasing a TMS software. In this article, we discussed the general hallmarks of a good TMS. However, after choosing the best software, it requires fine-tuning and tailoring to suit business needs that can vary significantly from other businesses in the industry.