Every transport manager dreads sudden vehicle breakdown - one truck stuck on the highway, a missed delivery, penalties stacking up, and customer trust fading away. The ugly truth? Many of these “surprises” are anything but. Often, these are the results of poor maintenance and, more specifically, a poorly managed service history.

Without a documented record of repairs, replacements, and inspections, businesses operate in the dark. Trucks may operate longer than they should without checks, spare parts may get replaced multiple times unnecessarily, and compliance deadlines missed. All of this translates into elevated costs, frequent downtime, and avoidable operational abnormalities. On the other hand, when service history is well documented, it becomes a tool that advances efficiency, cost optimization, and business growth.

Significance of Routine Fleet Maintenance

According to a logistics fleet survey, well-maintained vehicles last significantly longer - up to 40% higher functional life compared to those that don’t undergo maintenance. Moreover, modern service practices give your trucks an extra 20 - 30% lifespan extension. A systematic maintenance schedule ensures:

- Lower scope of sudden breakdowns

- Extended vehicle lifespan

- Better fuel efficiency

- Higher driver safety

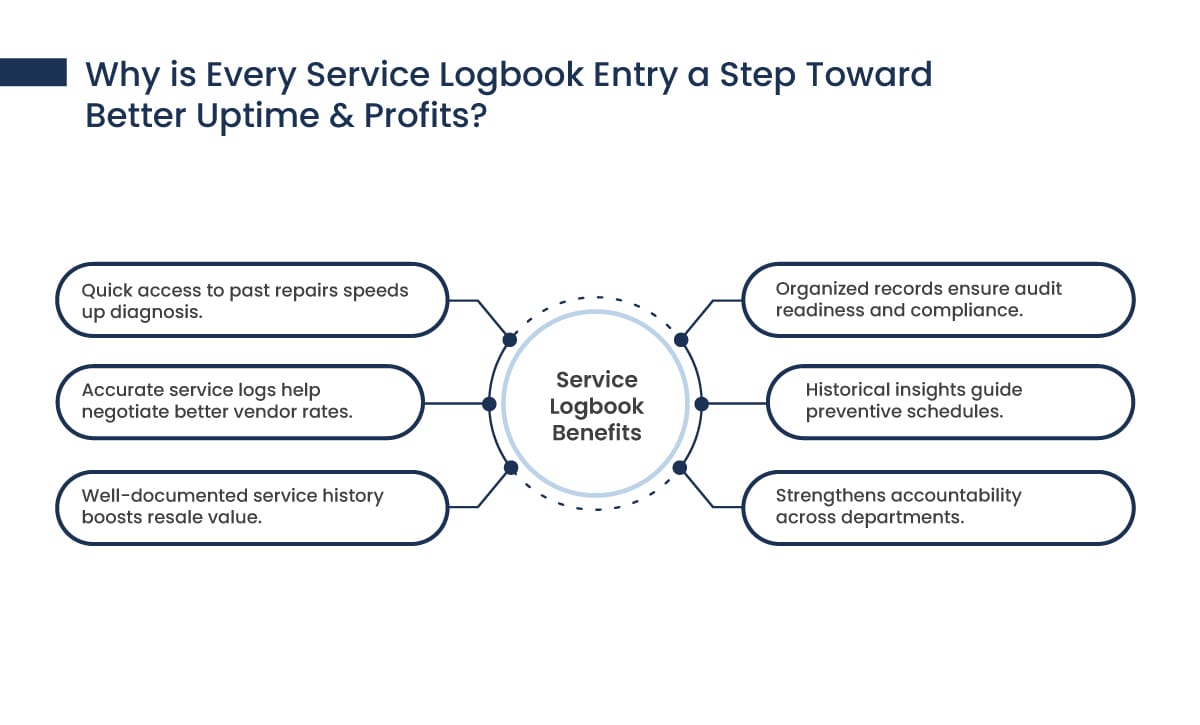

Top Reasons to Document Vehicle Service History

A well-maintained service log isn’t just about ticking compliance boxes; it’s a strategic asset that drives operational efficiency, safety, and profitability. Here’s why:

1. Reduces Downtime

Service records highlight recurring issues, allowing fleet managers to fix them before they escalate into expensive breakdowns. Downtime isn't cheap - unscheduled vehicle downtime can cost fleet operators heavily. That's lost revenue, driver wait-time, and disrupted schedules - suddenly, preventive care looks essential, not optional.

2. Optimizes Maintenance Costs

Tracking vehicle repairs and part replacements helps avoid task duplication and unnecessary business expenditure. A well-implemented preventive maintenance program can cut maintenance costs by 30%, significantly reduce breakdowns, and offer a return on investment of 300–500%.

3. Higher Resale Value

While exact figures for truck valuation in India are scarce, global data indicates that an organized maintenance record can increase resale value significantly - often by 10 to 15%, thanks to transparency and buyer confidence.

4. Ensures Compliance

In regulated industries, late or missing service documentation can attract penalties and downtime for non-compliance. While India-specific fines range from ₹5,000 to ₹25,000 depending on violations, the critical point is this: documented service history keeps the auditor satisfied and your truck healthy.

5. Boosts Safety

Mechanical failures are a major safety hazard. Preventive maintenance rather than reactive fixes drastically lowers incident risk. Plus, accident-related repairs can cost up to 10 times more than routine maintenance.

6. Enables Predictive Maintenance

With updated service logs, fleets can move from reactive to predictive strategies, identifying patterns such as recurring engine or brake issues. Predictive maintenance has been shown to reduce maintenance costs by 8 to 12% over preventive maintenance, and by up to 40% over reactive maintenance.

7. Supports Better Budgeting

With accurate maintenance logs, financial planning gets nailed. For instance, fleet managers would be aware that a clutch change every 1.5 lakh km costs X, or that tyre replacements happen every Y kms - and can forecast and negotiate better with suppliers. It’s cost-saving clarity.

Types of Fleet Service Logs

Not all logs are created equal - each has its purpose and focus. The main categories include:

- Preventive Maintenance Logs: Track routine checks like oil change, tire rotations, and brake inspections.

- Corrective Maintenance Logs: Record unplanned repairs resulting from sudden breakdowns.

- Inspection Logs: Daily/weekly/monthly inspection documentation carried out by drivers or technicians.

- Regulatory Logs: Necessary details required to comply with transport authorities and safety boards.

- Cost Logs: An account of expenses tied to every maintenance activity.

Key Elements Tracked in a Vehicle Maintenance Log

A complete service log should track the following:

- Vehicle details (make, model, VIN, registration number)

- Date and type of service performed

- Odometer reading at the time of service

- Parts replaced or repaired

- Service provider/technician details

- Cost of maintenance (parts + labor)

- Warranty details on parts replaced

- Next scheduled service date

- Notes on recurring issues or observations

Common Challenges & Consequences of Inadequate Maintenance of Vehicle Service Logs

Even with the best intentions, many transporters stumble when it comes to keeping logs accurate, consistent, and scalable. Here are the most common hurdles and what they really cost your business:

1. Human Error

Manual logging leaves plenty of room for mistakes - missed entries, incorrect odometer readings, or incomplete service details.

Business Cost: Inaccurate data leads to skipped maintenance, unexpected breakdowns, and inflated repair bills.

2. Fragmented Records

When different service vendors maintain their separate logs, the result is scattered information that doesn’t sync.

Business Cost: Without a centralized record, recurring issues go unnoticed, causing repeat breakdowns and unnecessary part replacements.

3. Lack of Standardization

Drivers, mechanics, and branch offices often use different formats for recording service details.

Business Cost: Non-uniform logs make audits painful and delay decisions, while compliance irregularities can trigger hefty penalties.

4. Delayed Updates

Repairs may be carried out promptly, but the logging often happens days or weeks later.

Business Cost: Missed or late entries reduce data reliability, making it impossible to schedule preventive maintenance effectively, leading to costly emergency repairs.

5. Over-Reliance on Paper Trail

Paper-based registers are prone to loss, damage, and tampering.

Business Cost: Lost service records can derail compliance audits and even halt operations if fitness certificates or inspection histories can’t be produced.

6. Scalability Issues

As fleet sizes grow, manual systems simply collapse under the weight of information.

Business Cost: Time wasted on chasing records, manually reconciling invoices, and re-entering data eats into productivity, while inconsistent logs across fleets inflate overall operating costs.

Ways to Maintain a Fleet Service Log

Maintaining a log may sound simple, but consistency is where most fleets falter. Here are some practical approaches:

- Digital Fleet Management Systems: Cloud-based platforms that automate scheduling and record-keeping.

- Driver Apps: Allow drivers to upload inspection reports and e-PODs in real-time.

- Centralized Databases: One place where all vehicle histories are stored for easy access.

- Automated Alerts: Reminders for upcoming maintenance or renewals.

- Integration with GPS/IoT Devices: Automatic odometer updates and health monitoring.

The key is to reduce manual dependency - because paper registers and spreadsheets almost always fail.

How Does Fleetx Streamline the Process of Maintaining Fleet Service History?

Fleetx turns vehicle maintenance tracking from a headache into a strategic advantage by digitizing and centralizing the entire process. Instead of juggling paper logs and scattered invoices, transporters get a complete, data-backed view of every vehicle’s health and costs in one place. Here’s how the platform makes it happen:

Service History Summary

Fleetx provides a consolidated summary of each vehicle’s service history along with the costs spent on maintenance. This gives fleet managers instant insights into what work has been done, how much has been spent, and which vehicles are draining resources.

Odometer-Based Tracking

After every service, Fleetx records the odometer reading automatically. This simple detail becomes a powerful tool for predicting the next service date based on kilometers driven, ensuring no truck misses its preventive maintenance window.

Cost Spent Analysis

Not all trucks are created equal - some cost more to keep on the road than they earn. Fleetx helps you monitor day-wise service costs, compare them against revenue, and identify vehicles that are turning into cost centers. With this data, you can make proactive decisions about overhauling, reassigning, or even replacing inefficient trucks.

Centralized Records

Every repair, inspection, and replacement is stored digitally in one place. No more chasing vendors for paperwork or worrying about misplaced invoices. Fleetx keeps your fleet’s entire service history audit-ready and accessible.

Actionable Insights

Beyond just logging data, Fleetx helps you analyze it. You can track maintenance cost per kilometer, per vehicle, or across the fleet. These insights guide corrective actions, budget planning, and long-term asset optimization.

Case Study: How Fleetx Transformed Maintenance for a Mid-Sized Fleet Operator

Client Overview

Our client is a mid-sized transporter based in Nagpur, operates a fleet of 120 trucks across interstate routes in India. The company caters to FMCG and automotive clients, where on-time delivery is non-negotiable.

Problem Statement

Despite having a dedicated operations team, RC Logistics struggled with inconsistent service history management. Records were scattered across registers, spreadsheets, and vendor invoices. This led to:

- Frequent breakdowns mid-route

- Escalating repair costs due to repeated fixes

- Missed compliance deadlines, attracting penalties

- Poor visibility into which trucks were driving up costs

The situation affected client trust and added 12–15% to annual operating expenses.

Solution Offered by Fleetx

Fleetx digitized and centralized RC Logistics’ entire maintenance history. The solution provided:

- Automated odometer-based tracking to schedule preventive maintenance accurately

- Centralized digital records accessible across depots and workshops

- Cost spent analysis to identify high-maintenance vehicles

- Custom alerts & reports for compliance deadlines and part replacements

Solution Benefits

Within 12 months of using Fleetx, RC Logistics reported:

- 30% reduction in maintenance costs by eliminating duplicate repairs and optimizing vendor negotiations

- 40% drop in unplanned downtime thanks to timely preventive care

- Improved compliance with audit-ready records, avoiding penalties

- Better asset-related decisions wherein two underperforming trucks were replaced, saving long-term costs

Fleetx transformed the service logs from paperwork into a profit lever, restoring customer trust and strengthening competitiveness.

Take Complete Control of Your Maintenance Activities

In logistics, downtime is lost profit. A truck that isn’t on the road is a truck that isn’t earning. Poor service history management silently eats into margins, but the fix is straightforward: document, analyze, and act.

With a robust maintenance log—and the right digital tools to manage it—transporters can cut surprises, control costs, and win customer trust. Fleetx empowers fleets to take complete control, ensuring every truck is road-ready, every expense is accounted for, and every delivery is on time.

The message is clear: service history isn’t paperwork—it’s your growth strategy.

Why is maintaining a vehicle service history so important in fleet operations?

A documented service history reduces downtime, cuts maintenance costs, improves resale value, ensures compliance, and boosts safety. It transforms maintenance from reactive firefighting into a proactive strategy that extends truck life and builds customer trust.

What challenges do transporters face when maintaining service logs manually?

Manual or paper-based logs often suffer from human error, fragmented records, delayed updates, a lack of standardization, and scalability issues. These problems lead to higher costs, repeat breakdowns, and compliance risks.

How does Fleetx simplify fleet service history management?

Fleetx digitizes and centralizes maintenance data, offering odometer-based tracking, cost analysis, automated reminders, and consolidated records. It not only logs service activities but also generates actionable insights for cost control, compliance, and long-term asset planning.

Can proper service history management really reduce costs and downtime?

Yes. A well-kept service log can lower maintenance costs by up to 30%, prevent unnecessary repairs, reduce breakdowns, and improve fuel efficiency. By predicting service needs and optimizing schedules, fleets minimize unplanned downtime and protect profits.