Businesses have evolved through decades of transformation into how they function today and most of the credit goes to technology and how it has made every aspect of conducting businesses better. Throughout history, whether it was automation in manufacturing or GPS tracking for supply chain efficiency, technology integration has withered several roadblocks to make business operations better, more efficient and transparent.

Today, we stand at the cusp of a new era where technologies like Artificial Intelligence, Automation, and Internet of Things (IoT) among others will fundamentally change how businesses function. In the case of supply chain, what we are looking at is the fourth revolution or Supply Chain 4.0 but more on that later. However, the supply chain industry has had its own sets of challenges with technology integration that are very much visible even today. In the Indian context, several businesses across industries have been adopting technology integration in supply chain management, however, a larger section of businesses continue to resist adopting technology and continue to manage their supply chain operations in the traditional way which has been proven to be costlier, inefficient and lacks transparency in operations.

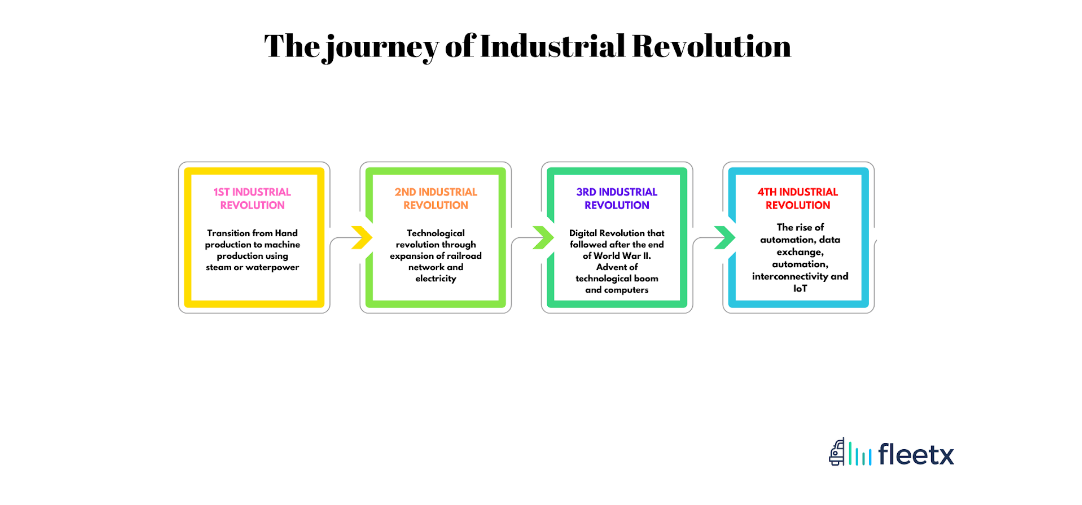

A brief history of industrial revolutions

Before understanding Supply Chain 4.0, it's important to understand how industries revolutionised over centuries into what we know today as Industry 4.0. Currently, business circles and conclaves are buzzed with terms like Industry 4.0 or 4IR, which experts use to define how industries function or will function in the 21st century. The term was first coined by Klaus Schwab, Founder-Chairman of the World Economic Forum, in 2015 and conceptualised the rapid change in technology, industries and societal patterns due to increasing interconnectivity and smart automation. Rapid change is guided by technologies like AI, robotics & automation, smart technologies, and IoT, among others. Moreover, the emphasis on machine-to-machine communication (M2M) to improve how different business processes integrate appears to be a key USP of industry 4.0.

We have come a long way since the first industrial revolution, and subsequent industrial revolutions have transformed our lives unimaginably. And if history has taught us anything, technology will change things for the better. Speaking from a business perspective, the fourth industrial revolution or Industry 4.0, is about transparency, interconnectivity, and efficiency.

How technology revolutionised supply chain

The supply chain has been at the centre of industries and business operations. One of the biggest achievements of humankind is the ability to move goods from one part of the world to another. The second industrial revolution was about improving the way goods are transported, which led to the invention of railways which became the backbone of the modern supply chain as we know it today. Before that, ships were the only major source of transporting goods across different parts of the world.

The existence of supply chain networks across the world connecting every nook and corner allowed globalisation to materialise. Globalisation has become the centrepiece of modern society, making it possible for us to have goods that can be brought to us within such a short time and made using parts sourced from around the world. From a cost perspective, globalisation and efficient supply chain networks have made it possible for goods to be produced, shipped and consumed at scale while still ensuring their cost-effectiveness. For example, modern smartphones have hundreds of components produced, assembled and fitted across different parts of the world due to the comparative advantage each business, country or region would have in producing those parts. Comparative advantage allows businesses to produce goods they specialise in and, thus, helps make them cost-effective. The entire process, from sourcing materials to production to shipping to consumption, is made possible by a technology-driven supply chain functioning efficiently in the background.

Supply chain related challenges faced by businesses

Global supply chain networks have driven consumption, made business processes efficient and improved quality of life. However, they have also increased complexities regarding logistics and transportation of goods. Modern supply chain management is extremely interdependent and complex. So much so that even a small hiccup or bottleneck could sometimes choke the entire supply chain. The most recent example is how the shortage of semiconductor chips had choked the entire supply chain of automobile manufacturers. It led to a severe global crisis affecting all aspects of the economy due to its interconnected nature. Even today, prices of almost every good that requires electronic chips have gone up in the past two years, giving an overview of how serious unforeseen circumstances could affect the supply chain across industries.

Similarly, complex supply chain networks have created several blindspots in business operations and transparency issues that have become harder to navigate as businesses scale their operations. These blindspots in supply chain management continue to create compounding problems for businesses and their operations, eventually causing a loss of efficiency and revenue either directly or indirectly. The inefficiencies in supply chain operations vary across different aspects of supply chain management. Some of the key supply chain inefficiencies include,

- Lack of supply chain visibility in operations

- Fuel and cargo theft

- Inefficient fuel management

- Route planning and navigation related challenges

- Issues related to vehicle breakdown and fleet maintenance

- Issues with cold chain logistics

The list of supply chain issues is not comprehensive, and supply chain issues vary across industries and business functions. However, these issues are not incurable, and most of them can be resolved. As someone truly said, with the rise in complexities, comes a rising number of solution providers. And indeed, there have been solutions to tackle these inefficiencies in supply chain operations.

Why Supply Chain 4.0 is the future of supply chain management

Solutions to tackle supply chain inefficiencies are deeply intertwined with technology integration in supply chain management. These discussions are not happening in silos, and businesses and supply chain providers worldwide are adopting technology to improve their supply chain operations. Amazon is a poster boy for championing the cause of technology integration in supply chain operations. It took 3PL logistics and built an empire on the backs of supply chain efficiency, thus pioneering processes and functions like same-day delivery, and lean logistics, among several others. What Amazon did to the supply chain industry through technology integration, data-driven decision-making, automation, and supply chain visibility are all by-products of Supply Chain 4.0. One could even go as far as to say they showed businesses around the world why businesses need to get their supply chain right.

However, businesses continue to resist technology integration, particularly in India, where the logistics sector is extremely unorganised. Several businesses and transporters are unwilling to shift to Supply Chain 4.0 for various reasons, such as the high acquisition cost and disregarding the long-term sustainability and benefits of making the shift.

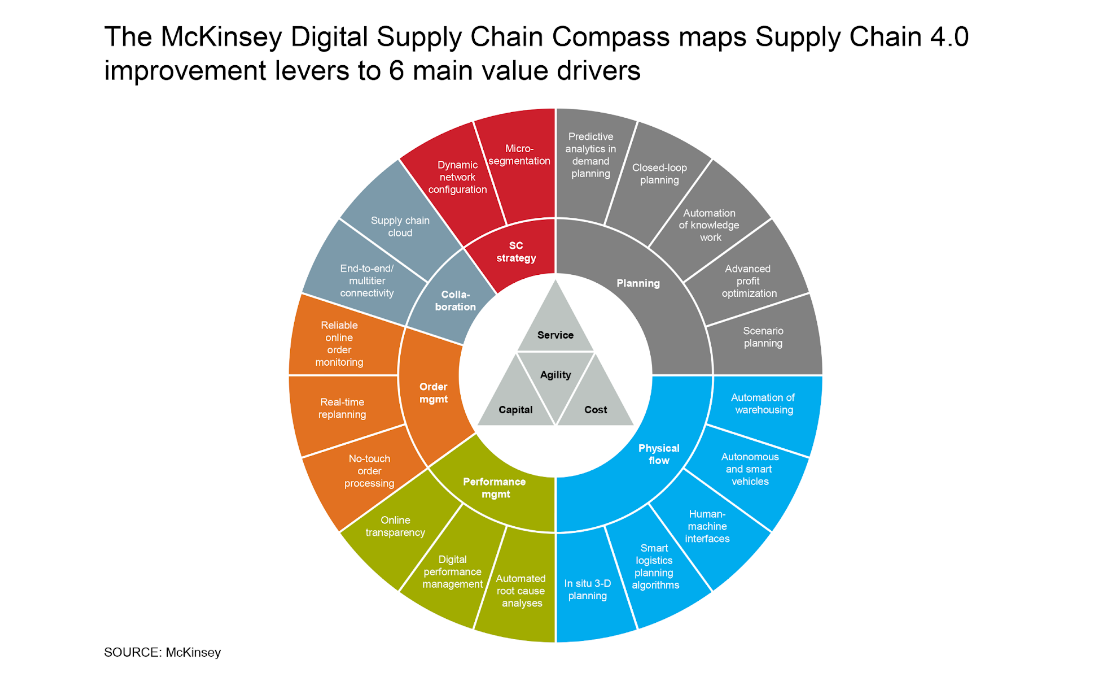

Understanding a shift to Supply Chain 4.0 means for businesses

For simplicity, let’s understand Supply Chain 4.0 this way, consider a large mesh where everything is connected (IoT). Machine-to-Machine communication (M2M) is highly optimised. Every aspect of supply chain operations is interconnected, capturing data through hardware sensors and transmitting it. This large mesh dynamically collects data, processes it, and uses it to eliminate inefficiencies in supply chain operations. As a business owner, you have complete visibility of every business process and have access to terabytes of data collection from different aspects of the operations, which can be analysed to improve business forecast, predict demand and use it as you see fit. That’s what supply chain 4.0 is all about.

Each system operates through hardware sensors such as a BlackBox installed in each vehicle that collects, processes and transmits data. Through supply chain 4.0, businesses will be able to leverage all the data across different functions to be collected at a granular level which would improve decision making and provide complete transparency over the entire operation, thus, improving efficiency and cost-effectiveness.

Conclusion

To conclude, Supply Chain 4.0, like industrial revolutions over centuries, will reshape how businesses manage their supply chain. Early adopters of the technology will greatly benefit from it, thus, having a competitive edge over their competitors. In contrast, late adopters will be forced by circumstances to either adopt or risk losing revenue to their competitors.

Is supply chain 4.0 and Industry 4.0 same?

The upgraded supply chain, known as supply chain 4.0, uses a number of Industry 4.0 technologies, including IoT, AI, cloud computing, and big data. To dramatically enhance supply chain management, it blends cutting-edge AI algorithms, business intelligence tools, data sciences, and other next-gen technology.

What is supply chain management 4.0 and its benefits?

Supply chain management 4.0, uses a number of Industry 4.0 technologies, including IoT, AI, cloud computing, and big data. By encouraging and lowering delivery times to only a few hours, it primarily enables and optimizes the flow of goods, information, and money, enabling businesses to increase overall business efficiency and build stronger relationship value.